ULT Energy-saving Series

After-sales Service Manual

46

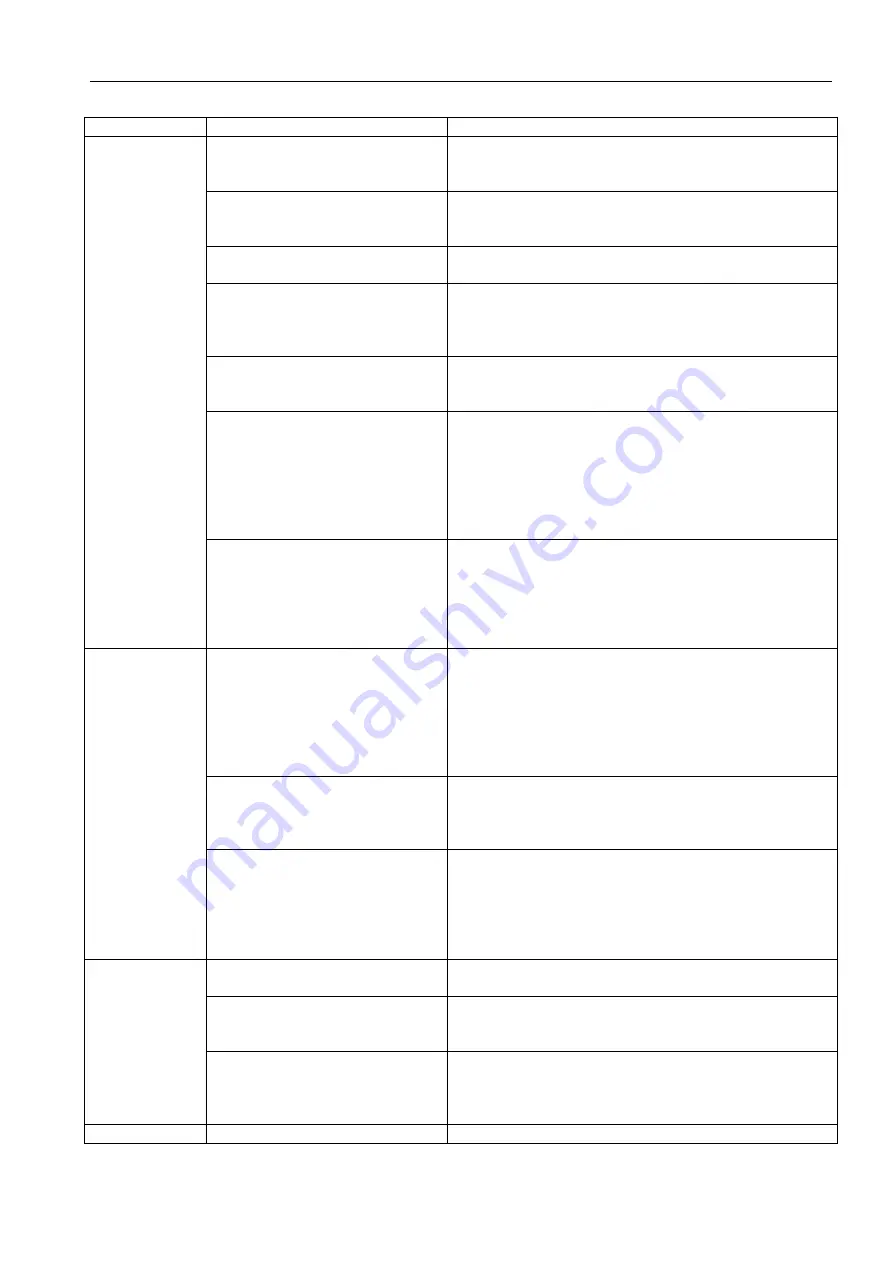

12.2 Troubleshooting of common problems

Problem

Cause analysis

Maintenance measures

1. High

temperature

stage

compressor does

not start

1. Power switch or fuse fault

Measure the resistance of the switch or fuse with a

multimeter, if it is confirmed that the switch is broken,

replace the fuse or power switch.

2. The connector for machine

compartment is damaged.

Check whether the socket of machine compartment

connecting wire is damaged or the harness is dropped, and

replace the corresponding patch cord.

3. Poor wire contact

Check whether the patch cord is poorly connected or not

connected, and repair it until the connection is normal.

4. Wiring fault of display board

and control board

Measure the resistance of the connecting wire with a

multimeter to determine the harness short circuit or open

circuit fault, and then replace the harness if it is unable to

be repaired.

5. Relay, starting capacitor or

thermal protector is out of order

Check the relay, capacitor or thermal protector for signs of

burned black or scorched of electrical parts, and replace

the electrical parts if it is the case.

6. Compressor fault

In other cases with normal power on, check whether the

connection plug of the compressor is normal, and observe

the surface temperature and the abnormal noise, etc. of the

compressor at the same time. If the compressor is not hot

or the noise is abnormal, the compressor is out of order, so

replace the compressor; when replacing the compressor,

the oil separator and dry filter should be replaced as well.

7. Too low voltage of the user

Check whether the voltage on the display board of the

product is within the rated range (220±10%). At the same

time, use a multimeter to measure whether the voltage is

overvoltage under the condition of power on. If the voltage

is too low or too high, the customer is required to provide

a voltage regulator.

2. Low

temperature

stage

compressor does

not start

1. Same as the causes of not

starting

of

high

temperature

compressor

In other cases with normal power on, check whether the

connection plug of the compressor is normal, and observe

the surface temperature and the abnormal noise, etc. of the

compressor at the same time. If the compressor is not hot

or the noise is abnormal, the compressor is out of order, so

replace the compressor; when replacing the compressor,

the oil separator and dry filter should be replaced as well.

2. Pressure switch is out of order

Measure the harness of pressure switch with a multimeter

for short circuit and open circuit, and at the same time,

check whether the copper pipe of pressure switch is

damaged, and replace the pressure switch in case of fault.

3. Poor refrigeration of high

temperature stage system

If the low temperature compressor does not start after 10

min of the startup of high temperature stage system, it

indicates poor refrigeration of high temperature stage

system. Check whether the circuit and pipeline welding of

high temperature stage system is good (if any blockage

and leakage), and deal with the fault.

3. The fan does

not work

1. The fan is dropped

Check whether the fan connector wire is dropped or not,

and reprocess the wire head and butt installation

2. Fan blade are blocked by foreign

matters

Check whether there is wall collision noise or not in the

rotation of fan blades, treat the blades and surrounding

foreign matters, and keep the blades running normally.

3. The fan is out of order

Measure the resistance at both ends of the fan wiring with

a multmeter and check for short circuit or open circuit, and

observe whether the rotation shaft rotates at the same time.

If as the cases above, please replace the fan.

4. High

1. High setting temperature of Check whether the setting temperature of the product is set