5.52.290.00.01.08

19

12.3.3

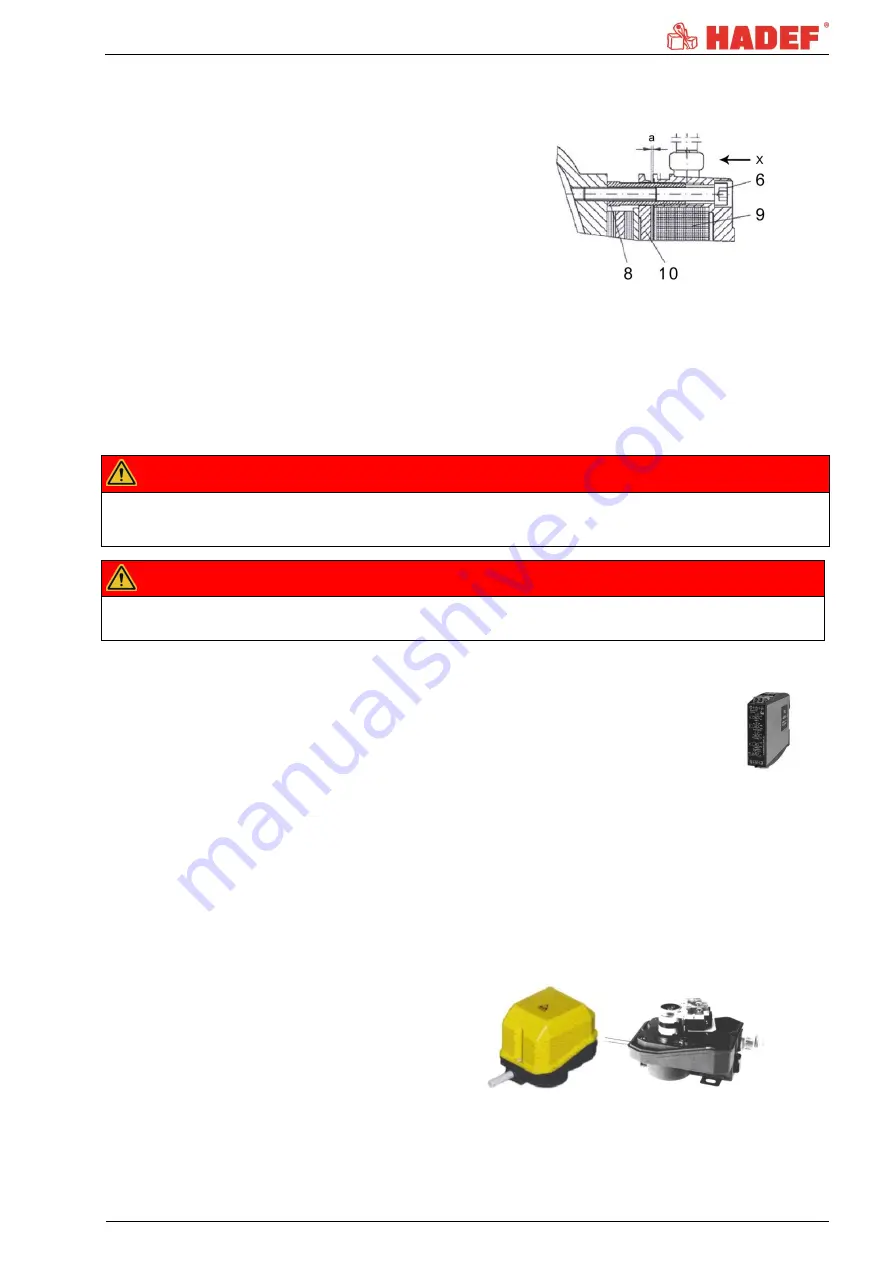

Adjusting the air gap

View "X" on the brake.

1 Loosen the locking screws (6) by half a turn.

2 Turn the cap screws (8) into the magnetic body

(9) anti-clockwise.

3 By turning the locking screws (6) clockwise,

move the magnetic body (9) towards the

anchor plate (10) using a feeler gauge until

nominal air gap “a” is reached (see table).

4 Unscrew the cap screws (8) from the magnetic

body clockwise.

5 Tighten the locking screws (6).

6 Check the air gap again and re-adjust if

necessary.

Illustration 18

12.4

Overload protection

If the hoist does not lift the permitted load, the overload protection must be adjusted. Adjustment may only be

done by a service company, authorised by the manufacturer!

DANGER!

The factory setting of the overload protection is secured by a seal. Any guarantee becomes invalid if this setting is

changed. Should maintenance be necessary, please contact a service company that is authorised by the

manufacturer.

DANGER!

The overload protection serves exclusively to protect against damage to the device due to overloading

when moving loads. Its function must not be integrated into the operational work process!

Depending on the type of hoist, the following variants are possible:

12.4.1

Electronic hoisting power limiter (as option, except serial AT)

Power consumption of the hoist motor is measured during lifting movement of a load

by an adjustable power measuring device (overload guard). The setting is made via a

separate relay for main and creep lifting speed. Power consumption of the motor is

load-dependent and increases with the load. If the set value is exceeded, the relay

responds and switches the motor off via switching elements. After the overload

protection has been activated the LOWER button must be pressed first so that the

LIFT function can be activated again. Before lifting again the load must be reduced to

the nominal load!

Illustration 19

12.5

Limit switch for wire rope path (as option)

12.5.1

Setting of the switching points

At first, adjust the cams for "lowering". Therefore lower the load to its lowest end position and adjust the

cams. The number of switching cams can vary job-oriented.

1 Unscrew the screws of the cover and remove

the cover.

2 Loosen the central screw (1)

3 Set the switching point of every cam disc

(A,B

…and possibly other) with set screw

(2A,2B

…and possibly other).

4 Tighten the central screw (1) again.

5 Install the cover again and make sure the

rubber seal is placed correctly.

Illustration 20