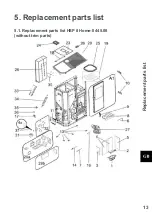

14

Replacement

parts

list

Pos.

Description

Piece

No. PR

Replacement

parts

list

HSP

8

Home

-II 445.08

(without

trim

parts)

A1

Complete combustion chamber door/pearly-

black

1 piece

0544208005300

1

Burner cast

1 piece

0544208006762

2

Protection grate

1 piece

0544208006713

3

Combustion chamber cladding left

1 piece

0544208005507

4

Combustion chamber cladding back

2 piece

0544208005505

5

Combustion chamber cladding right

1 piece

0544208005506

6

Flame temperature sensor

1 piece

0544008007511

7

Bottom temperature sensor

1 piece

0544008007539

8

Draught baffle plate

1 piece

0544208005752

9

Door contact switch

1 piece

0089500040005

10

Door hinge pearly-black

1 piece

0544008005450

11

Complete control unit

1 piece

05

5

1908005569

12

Backup battery CR 2032

1 piece

—

13

Stand

6 piece

0082000105000

14

Ignition

1 piece

0541908005202

15

Room temperature sensor

1 piece

0089500390005

16

Flue gas thermosensor

1 piece

0561008005540

17

STB

1 piece

0089500080005

18

Cover hinge

2 piece

05445080

46113

19

Protective grille

1 piece

05445080

45971

20

Cover pearly-black

1 piece

05445080

4

6180

23

Tank cover pearly-black

1 piece

05445080

46150

24

Operator console

1 piece

05

51908005569

25

Seal, tank cover

1060 mm

05445080

4

5929

26

Handle

1 piece

0544008007581

27

Induced draught fan

1 piece

0561008005807

28

Heat exchanger

1 piece

0544

0

08006000

29a

Seal - set

10 piece

0544508015011

29b

Seal - set cleaning

2 piece

0544408005012

30

Tank cover + screw DIN 7981 ST 4,8x13 - set 1+4 piece

0544008005019

31

Screw conveyor motor

1 piece

0089500000006

32

Motor plate - set

1 piece

0561008007080

33

Conveyor

1 piece

0544008005938

34

Screw conveyor

1 piece

0544008007090

35

Lower screw conveyor bearing

1 piece

0544008007047

36

Collet

1 piece

0089000340005

37

Screw UN5950 M5x10

4 piece

—

Summary of Contents for HSP 8 Home-II 445.08

Page 4: ......

Page 6: ...Dimensions 2 2 Dimensions...

Page 13: ...Maintenance work 9 4 3 c 4 3 d...

Page 21: ...17 6 Circuit diagram Circuit diagram IO 33 3 Circuit diagram...

Page 23: ...19...

Page 24: ......