Summary of Contents for HSP 8 Home-II 445.08

Page 4: ......

Page 6: ...Dimensions 2 2 Dimensions...

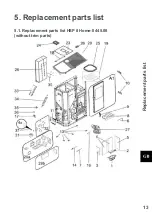

Page 13: ...Maintenance work 9 4 3 c 4 3 d...

Page 21: ...17 6 Circuit diagram Circuit diagram IO 33 3 Circuit diagram...

Page 23: ...19...

Page 24: ......