6

4.2. Cleaning the flue gas passes - annual maintenance

CAUTION

We therefore recommend checking and/or cleaning the flue gas passes after 1,000 kg of pellets at the latest.

To clean the flue gas passes, proceed as follows:

• Disconnect the flue baffle (1) from the guide by lifting it. Draw the right cladding (2) down out of the guide

and place it down in the ash space. Then the flue baffle can be removed and the upper part of the

combustion chamber can be cleaned. (See Figure 8).

• Then remove the right side wall. This is fixed with screws (1) at the back and at the front with 3 connectors.

Remove the screws from the back and pull the side wall off sideways. (See Figure 1a-2h).

Figure 8: Removing the flue baffle

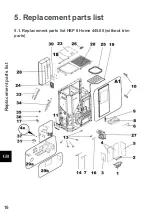

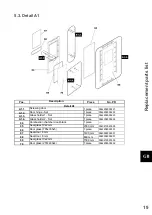

Summary of Contents for HSP 8 Home 445.08

Page 4: ......

Page 6: ...Dimensions 2 2 Dimensions ...

Page 11: ...Maintenance work 7 2 a 2 b ...

Page 12: ...Maintenance work 8 2 c 2 d ...

Page 13: ...Maintenance work 9 2 e 2 f ...

Page 16: ...Maintenance work 12 4 3 c 4 3 d ...

Page 17: ...Maintenance work 13 4 3 e 4 3 f ...