094148_k_gb_hseilw_s

haacon hebetechnik gmbh – Tel49 (0) 9375 - 84-0 – Fax +49 (0) 9375 - 8466

1

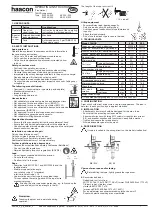

1. USER GROUPS

Duties

Qualifications

Operator Operation,

visual inspection

Instruction by means of the operating

instructions; Authorised person 1

Special-

ist per-

sonnel

Assembly, disassembly,

repair, maintenance

Mechanic

Tests

Authorised person 2 per TRBS-1203

(Technical expert)

2. SAFETY INSTRUCTIONS

Appropriate use

Operate the equipment in accordance with the information in

these operating instructions.

– Only use to lift, lower and pull freely-movable loads.

– Only use when in perfect working order.

– Only allow to be operated by personnel instructed on how

to do so.

Safety-conscious work

– First read the operating instructions.

– Always be conscious of safety and hazards when working.

– Observe lifting device and load during all movements.

– Immediately report any damage or defects to the person in charge.

Repair equipment first before continuing work!

– Do not leave the load suspended without supervision.

– Transport device protected against impacts and shocks, falling over

or toppling.

The following are not allowed:

– Overload (--> technical data, type plate, payload plate)

– Mechanical propulsion.

– Impacts, blows.

– Long lowering operations.

Use exclusions

– Not suitable for permanent operation and vibration stress.

– Not approved for use as builders' hoist (BGV D7).

– Not approved for use on stages or in studios (BGV C1).

– Not approved for use as a retractable transportation device

for personnel (BGR 159).

– Not approved for use in explosive areas/environments.

– Not suitable for aggressive environments.

– Not suitable for lifting hazardous loads.

Organisational measures

– Ensure that these operating instructions are always at hand.

– Ensure that only trained personnel work with the equipment.

– Check at regular intervals whether it is being used in a safety and

hazard conscious manner.

Installation, service and repair

Only by specialist personnel!

Only use original spare parts for repairs.

Do not modify or alter safety-relevant parts!

Additional attachments must not impact safety.

Further regulations to be observed are

– German Industrial Health and Safety Ordinance (BetrSichV).

– Country-specific regulations.

– German Accident prevention regulations (BGV D8).

Load

– Do not leave suspended without supervision.

– Do not allow to swing.

– Do allow to fall in the rope.

Rope

– Compliant with EN 12385-1 and EN 12385-4 and the

technical data

– Maintain rope deviation angle

non-rotating rope

≤

3° (standard)

rotation-resistant rope

≤

1.5°

– Use a rotation-resistant rope for unguided loads.

This can reduce the resting period of the rope (drive

mechanism group).

–

Wind up the wire rope under pretension, e.g. fully wind up the

rope and adjust the rope length to the lift.

Prohibited:

Touching the drum and rope intake during

operation!

The length of the rope is correct if:

> 3

> 1.5 x rope Ø

Lifting equipment

– Ensure sufficient load-bearing capacity.

– Only use load hooks with a safety flap.

– Use the approved load hooks with rope thimbles and

rope clip.

– Attach the load properly.

– Do not use the winch rope to secure the load.

3. TECHNICAL DATA

Model: TANGO

300

500

Order no., wall winch, galvanised

205986

205987

Order no., bracket winch, galvanised

207099

207118

Order no., wall winch, rust-free stainless steel

207117

207120

Order no., bracket winch, rust-free stainless steel

207117

207120

Nominal load

kg

300

500

Minimum load

kg

30

50

First layer

Rope pulling force

kg

300

500

Rope take-up

m

4,0

3,2

Max. number of layers

6

5

Final layer

Rope pulling force

kg

185

320

Rope take-up

m

29

22

Rope diameter

mm

4

5

Drive mechanism group1)

1Dm

1Dm

Minimum breaking force

kN

8,9

14,8

Crank force

N

160

200

Lift / crank

rotation

1. layer

mm

65

46

Final layer

mm

98

67

Weight without rope

kg

5,0

5,0

1) Drive mechanism group acc. to DIN 15020 and FEM 9.511

4. CONFIGURATION

Drum winch with direct drive or via a single-stage gearbox. The load is

held fast in each position by a load pressure brake.

5. INSTALLATION

– Attachment structures should be designed for the max. force

– Ensure that the mounting surfaces are flat

– Secure wall winches with three M12 screws (strength class at least

8.8), and bracket winches with four screws, each with a washer

– Tighten and secure the screws evenly

– Provide adequate space for the crank.

6. ROPE DIRECTION

If rope is inserted in the wrong direction, the brake is ineffective!

WE/ WV

KE/ KV

Choice of wire rope and fastening

Before fitting the rope, lightly grease the rope drum.

z

Recommended ropes:

Galvanised, (not twist-free)

EN 12385, Tab. 12, 6x19 WC 1770 B sZ (former DIN 3060 SE znk 1770 sZ)

Ordinary ropes, stainless steel:

similar to EN 12385. 7 x 19

[previously DIN 3060 SE bk 1570 sZ (1.4401)]

For rope diameter and minimum breaking force, see point 3

Ropes with plastic sheathing are not permitted.

≤3°

≤1,5°

≤3°

≤1,5°

OPERATING INSTRUCTIONS

(Translation)

TANGO rope winch

Type WV 300/500

KV 300/500

WE 300/500

KE 300/500

GB

-

20° C

+50° C

Summary of Contents for TANGO KE 300

Page 3: ...094148_k_fr_hseilw_s haacon hebetechnik gmbh Téléphone 49 0 9375 84 0 Fax 49 0 9375 8466 3 ...

Page 7: ...094148_k_gb_hseilw_s haacon hebetechnik gmbh Telephone 49 0 9375 84 0 Fax 49 0 9375 8466 3 ...

Page 11: ...094148_k_ru_hseilw_s haacon hebetechnik gmbh телефон 49 0 9375 84 0 факс 49 0 9375 8466 3 ...