1

Preparing for installation

ESD prevention

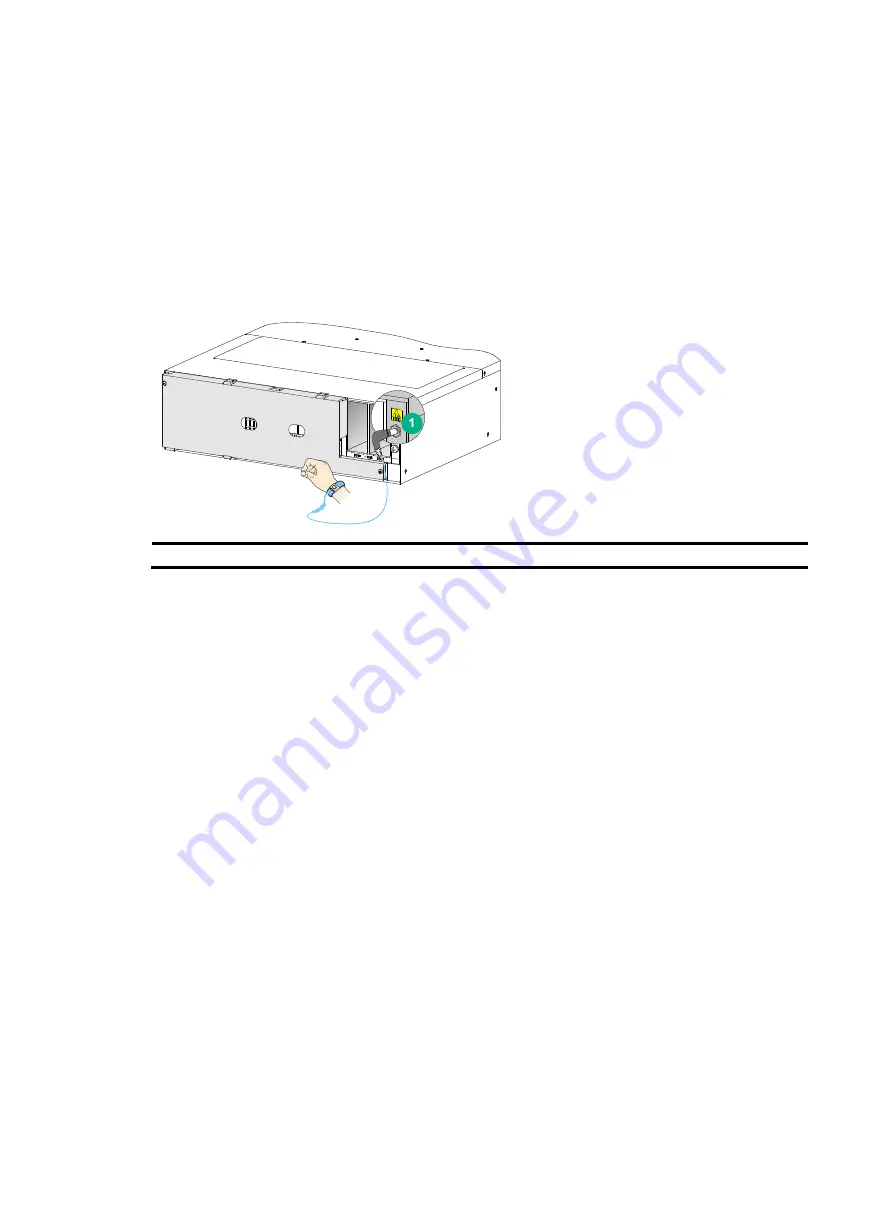

To prevent electronic components from electrostatic discharge (ESD) damage, wear an ESD wrist

strap and make sure it makes good skin contact and is reliably grounded before you touch any

switch module.

Figure 1 Attaching an ESD wrist strap

(1) ESD jack (with an ESD sign)

Examining the installation site

The switch must be used indoors. To make sure the switch operates correctly and to prolong its

service lifetime, the installation site must meet the load-bearing, temperature, humidity, cleanliness,

EMI, grounding, power supply, ventilation, and space requirements. Reserve a minimum of 1.2 m

(3.94 ft) of clearance between the switch and walls or other devices. For more information, see

H3C

S12500X-AF Switch Series Installation Guide

.

Installation tools and equipment

No installation tools and equipment are provided with the switch. Prepare them yourself.