10

SMARTFEED M-4

EN

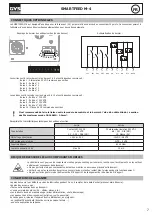

ELECTRO-MAGNETIC EMISSIONS

The electric current flowing through any conductor causes electrical and magnetic fields (EMF). The welding current generates an

EMF around the welding circuit and the welding equipment.

The EMF electromagnetic fields can interfere with certain medical implants, such as pacemakers. Protective measures must be taken for people having

medical implants. For example, by restricting access to passers-by or conducting an individual risk evaluation for the welders.

All welders must use the following procedures to minimize exposure to electromagnetic fields from the welding circuit:

• position the welding cables together - fix them with a clamp, if possible;

• position yourself (torso and head) as far away from the welding circuit as possible;

• never wrap the welding cables around the body;

• do not position the body between the welding cables. Hold both welding cables on the same side of your body;

• connect the earth clamp as close as possible to the area being welded;

• do not work too close to, do not lean and do not sit on the welding machine

• do not weld when transporting the welding machine or its wire feeder.

People wearing pacemakers are advised to consult their doctor before using this device.

Exposure to electromagnetic fields during welding can have other health effects that are not yet known.

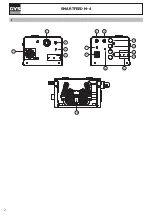

EQUIPMENT INSTALLATION

• Put the wire feeder on a floor with a maximum incline of 10°.

- Provide sufficient area to ventilate the feeder and access the controls..

• This equipment must be used and stored in a place protected from dust, acid, gas or any other corrosive substance.

- The dispenser must be protected from driving rain and not exposed to sunlight.

• The machine protection level is IP21, which means:

- Protection against acess to dangerous parts from solid bodies of a ≥12.5mm diameter and,

- Protection against vertically falling drops.

This material is designed for indoor use.

Power cables, extension leads and welding cables must be fully uncoiled to prevent overheating.

GYS does not incur any responsibility regarding damages to both objects and persons that result from an incorrect and/or

dangerous use of the machine.

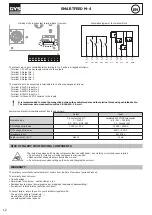

MAINTENANCE / RECOMMENDATIONS

• Maintenance should only be carried out by a qualified person. A yearly maintenance is recommended.

• Ensure the wire feeder is disconnected from the welding machine, and wait for two minutes before carrying out maintenance

work.

• Remove regularly the casing and any excess of dust. Take this opportunity to have the electrical connections checked by a qualified person, using

an insulated tool.

• Regularly check the condition of the connection cable between the wire feeder and the machine. If found damaged, the interconnection cable must

be replaced.

• Warning ! If the welding machine is transported/handled by another solution than the one recommended by the manufacturer; the wire feeder

casing must be insulated from the transporting/handling solution.

Rules to follow :

• The wire feeder must be switched on with all access panels closed.

Stray welding currents can damage earth connections, damage electrical equipment and cause overheating of components which

could result in fire.

- All welding connections must be firmly secured, check regularly !

- Make sure that the metal part fixation is strong and without any electrical problems !

- Attach or hang all the electrically conductive elements, such as the trolley or lifting systems in order to insulate them !

- Do not place any non-insulated electrical equipment such as drills on top of the welding machine or its trolley without insulating them!

- Always place welding torches or electrodes holders on an insulated surface when they’re not in use!