Supplied By www.heating spares.co Tel. 0161 620 6677

Page 25

GULFSTREAM

A-CL

ASS

5.5 CONTROL PANEL, DISPLAY & DIAGNOSTICS

The appliance controls fitted to the GulfStream

A-CLASS

have been designed to be fully

automatic and to provide functional and diagnostic information to the installer/

commissioning engineer.

5.5.1 Appliance model identification

In order to comply with the latest gas safety regulations, this appliance is fitted with

a model identification resistance. The controller reads this ID tag and compares it

with the appliance code set on the controller. The two must match for the appliance

to function. If there is a mismatch, the appliance will shut down safely and flag the

error message ‘33’ on the display.

The appliance ID data is shown in table 5.2 and the procedure for setting the appliance

code if a controller is replaced is described in section 5.5.3 (h)

(Warning: Under no circumstances should the appliance ID resistor be changed or

tampered with).

Table 5.2 Appliance ID data

Model

Appliance code

Appliance ID resistor

12 OV/SP

10

1K

20 OV/SP

20

1K5

30 OV/SP

30

2K2

If the boiler develops a fault (indicated by flashing red indicator light i.e. Led 3) then

proceed as follows:

1. If the red light is flashing

(a) Press button 1 to reset and return to gas boiler operatIon

(b) If the red light switches off - the fault has been cleared

(c) If the red light flashes again after 2 minutes - the fault has not been cleared.

Go to 2 below.

2. If the red light is still flashing

(a) Press button 2

(b) If the red light switches on permanent - the ‘switch’ electric backup has been

selected. Pressing button 2 again will deselect the ‘switch’.

(c) If red light continues flashing - ‘switch’ electric backup cannot be used.

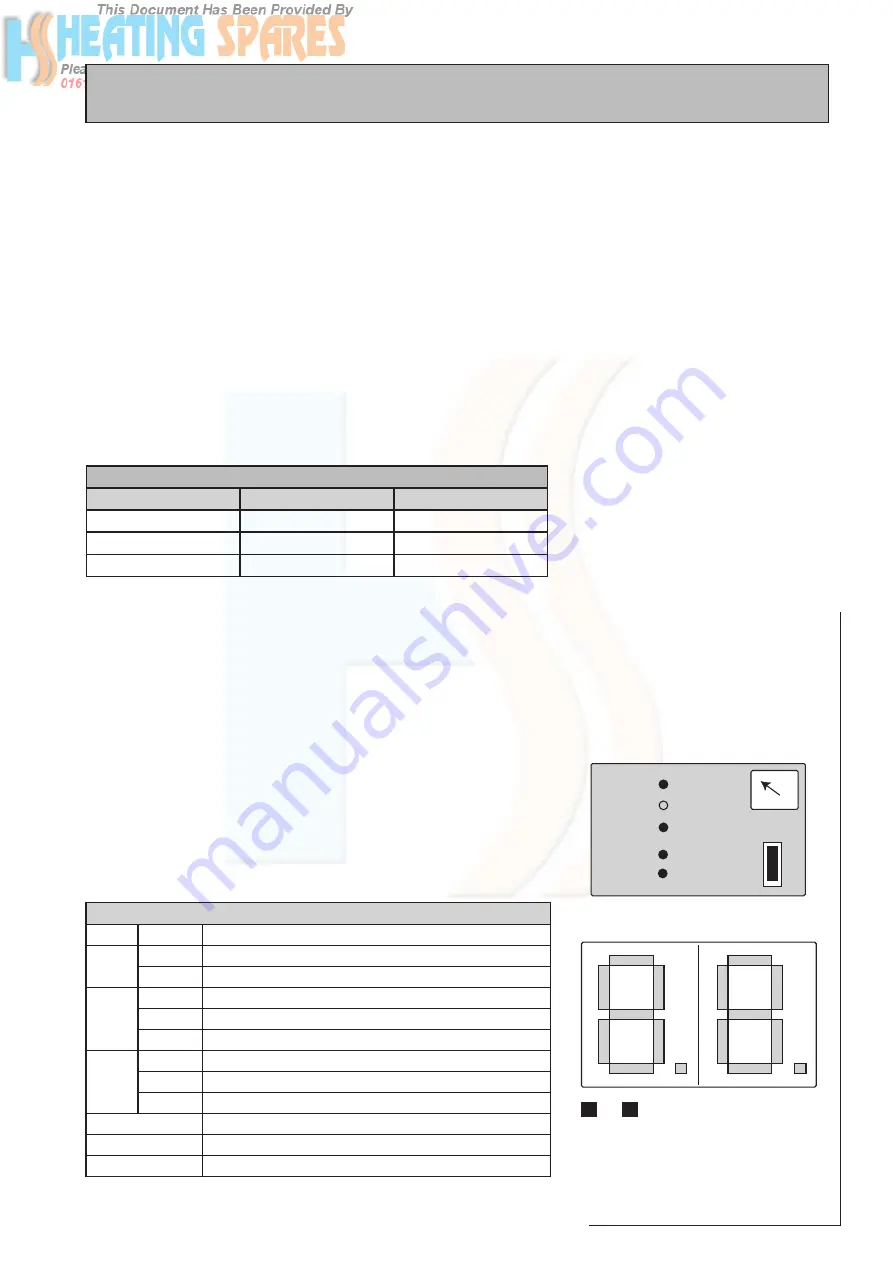

Table 5.3: Description of front panel controls

LED

Status

Function indication

Led 1

(green)

ON

Control circuit power supply is on

OFF

Control circuit power supply switched off or faulty

Led 2

(yellow)

OFF

Gas boiler in standby mode i.e. burner is off

FLASHING

Gas boiler is in ignition phase

ON

Flame has been sensed and the gas boiler (i.e. burner) is on

Led 3

(Red)

OFF

Gas boiler is in standby mode i.e. healthy

FLASHING

Boiler requires resetting e.g. lockout fault has occurred. (See below)

ON

Electric backup boiler has been selected (See below)

Push Button

1

Used to reset gas boiler and clear faults

2

Used to select ‘Switch’ electric backup

Figure 5.1: Front panel display

Figure 5.2 Display and push buttons on main

PCB

COMMISSIONING

�����

�����

�����

��������

��������

��������������

����������������

��

�

�

�

�

�

d1

D1.4

D1.7

D1.1

D2.4

D2.7

D2.1

D1.6

D1.5

D1.2

D1.3

D2.6

D2.5

D2.2

D2.3

d2

B1

B2

Figure 5.2 Display and push buttons on main PCB

5.5.2 Front Panel Controls

The operation of the appliance is indicated on

the front panel (figure 5.1) by green, yellow and

red indicator lights (LEDs). The push buttons

1 and 2 are used to reset the boiler and to

switch the backup electric boiler on /off in the

event of a gas boiler failure. The functions of

the front panel controls are described below

in table 5.3.

If the electric backup boiler has been selected,

(indicated by permanently ON Red Led_3). The

user can switch the electric backup boiler ON

and OFF by pressing Button_2. To permanetly

switch the electric boiler off and select the gas

boiler, switch OFF by pressing Button_2 and

then press Button_1.

5.5.3 Main PCB Functions & Diagnostics

The controller functions and faults are indicated

on the 2 digit display mounted on the main PCB

and the display functions are selected by the

push buttons B1 and B2 (figure 5.2). The flow

chart of the display mode is shown in figure 5.3.

The display functions are described below: -

(a) Normal mode: In this mode the display

(figure 5.2) is used to indicate the status

of different input demands and output

functions. The first left hand digit is used to

indicate demands sensed by the controller

and the second right hand digit indicates

the output functions of the controller.

This mode is selected by button B1 and the

display description is presented in table

5.4.

Summary of Contents for GS A-Class 12/OV

Page 39: ...Supplied By www heating spares co Tel 0161 620 6677 Page 39 GULFSTREAM A CLASS ...

Page 40: ...Supplied By www heating spares co Tel 0161 620 6677 Page 40 ...

Page 41: ...Supplied By www heating spares co Tel 0161 620 6677 Page 41 GULFSTREAM A CLASS ...

Page 42: ...Supplied By www heating spares co Tel 0161 620 6677 ...

Page 43: ...Supplied By www heating spares co Tel 0161 620 6677 ...

Page 44: ...Supplied By www heating spares co Tel 0161 620 6677 ...