GSK SJT series AC servo motor

16

Ⅸ

PROTECTION of the MOTOR

9.1 The motor structure is protected based on GB 4208—2008/IEC 60529: 2001

Cabinet Protection

Grade (IP Code)

, and IP65 grade of GB/T 4942.1—2006

Protection Grade (IP Code) of Rotation

Motor Overall Structure

. It prevents the human body from touching the dangerous parts in the motor

and interference from the external substance to guarantee the motor working normally. However,

most of the liquid, such as the cutting fluid and lubricant, etc is with the strong seepage force, and if

the motor touches such liquid for a long time, it may cause the motor can’t work normally or shorten

the service life. Therefore, the proper protection measure should be taken during the motor

installation and try to avoid contacting the above liquid and soaking the motor in the liquid, which is

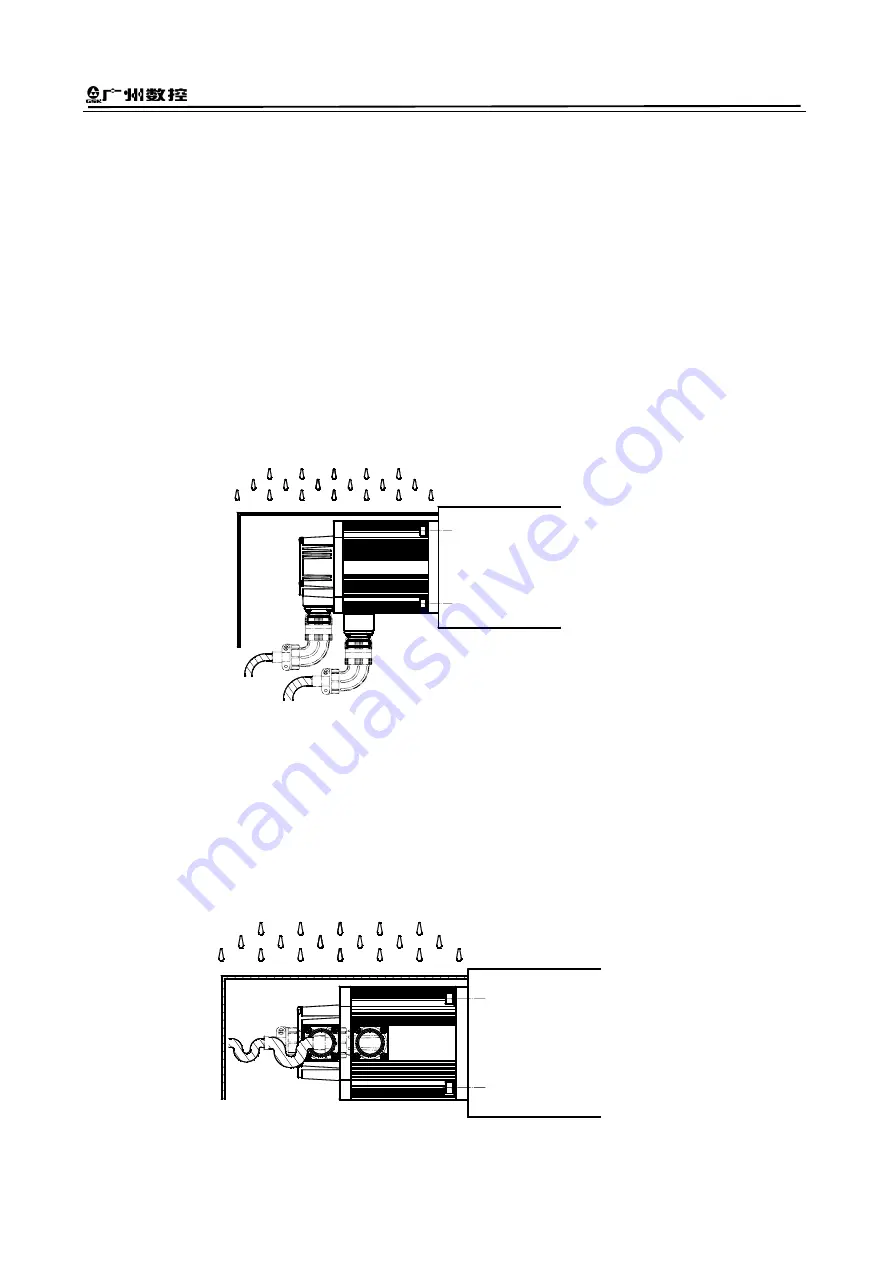

shown as figure 5.

Fig. 5

9.2 When the motor cables are arranged improperly, it may result the liquid, such as the cutting fluid,

gets together at the connector along the cable lead-in, further the motor malfunction. Therefore, the

motor connector side should try to get down or along the horizontal direction during installation,

which is shown as figure 5.

9.3 When the motor connector side gets along the horizontal direction, the cable should be bent as

the semi-circle of drop shape before connecting the connector, which is shown as figure 6.

Fig. 6