8. 16"-24" Head Platform Assembly

56

PNEG-1807CE

CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

Install Deck E

NOTE:

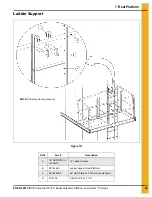

The orientation of the flanges on Deck E is important to proper assembly. Deck E flanges should

be to the outside of Deck A and Deck C.

1. Locate Deck E. It is the smallest deck.

NOTE:

Deck E will attach to Deck A, Deck C, both side toe boards and the main support channel.

2. Using a punch as needed for alignment, connect Deck E to the side toe board using 3/8" x 1" carriage

bolts (S-3585) with flange nuts (S-10028). Torque to standard specifications.

a. Deck E hole

E1

to Deck A hole

A5

.

b. Deck E hole

E2

to Deck A hole

A4

.

c. Deck E hole

E3

to Deck C hole

C5

.

d. Deck E hole

E4

to Deck C hole

C4

.

Figure 8H Deck E, Deck A and Deck C as Viewed from Underneath.

DECK A

DECK C

16"-24" Decks E, A and C - Underneath View

DECK E