English (GB)

21

10.6 Fault finding chart

11. Maintenance

11.1 General notes

11.2 Cleaning and maintenance intervals

11.2.1 Changing the gear grease

To ensure trouble-free operation, it is recommended to have the

gear grease changed after five years or after 20000 operating

hours.

11.2.2 Cleaning the diaphragm and valves

Clean the diaphragm and valves, and replace if necessary

(with stainless-steel valves: inner valve parts):

• At least every 12 months or after 4000 operating hours.

When operating with a counterpressure of 16 bar, every six

months or after 2000 operating hours.

• In the event of a fault.

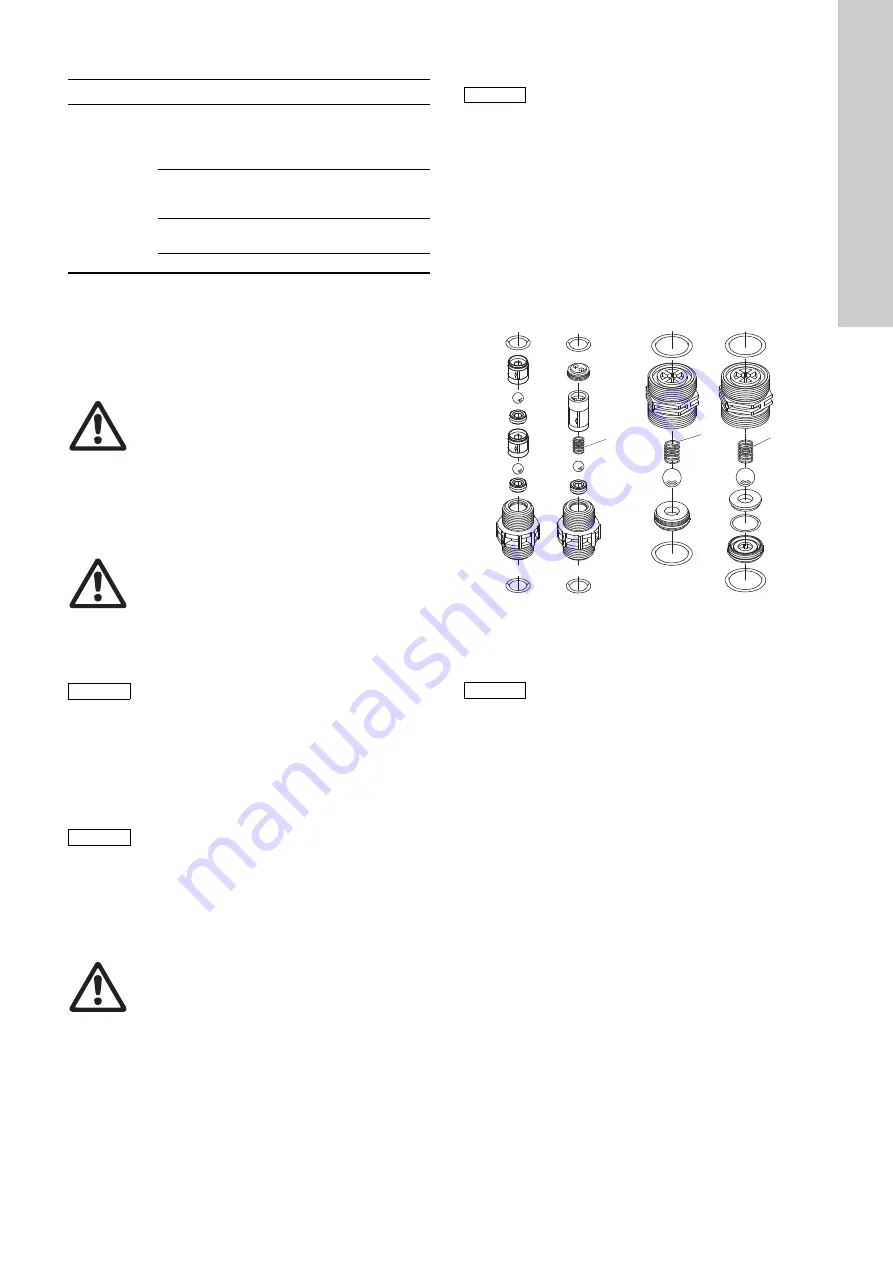

11.3 Cleaning the suction and discharge valves

If the pump loses capacity, clean the suction and discharge

valves as follows:

1. Unscrew the valve.

– DN 20

Unscrew the screw part resp. valve seat with round pliers.

– DN 8

Press out the valve cartridge and remove the valve seat

from the ball cage.

2. Clean all parts. Replace faulty parts by new ones.

3. Re-assemble the valve.

4. Replace the O-rings by new ones. Refit the valve.

Observe the direction arrow on the valve.

Fig. 26

Stainless-steel or plastic valve DN 8 / DN 20,

* spring-loaded as an option

11.4 Maintenance of the relief valve

11.4.1 Cleaning and maintenance intervals

Clean the relief valve, and replace the diaphragm, if necessary.

• At least every 12 months or after 8000 operating hours.

• In the event of a fault.

11.4.2 Replacing the diaphragm of the relief valve

1. Switch off the pump and disconnect it from the power supply.

2. Make it impossible for a return flow or overpressure to occur.

3. Loosen the four screws on the top part of the relief valve.

4. Remove the top part of the relief valve.

5. Remove the diaphragm.

6. Insert a new diaphragm.

7. Refit the top part of the relief valve and cross-tighten the

screws.

Maximum torque: 6 Nm.

8. Start up the dosing system.

9. Tighten the screws on the top part of the relief valve after

48 operating hours.

Maximum torque: 6 Nm.

Fault

Cause Remedy

Permanent

output from

the relief

valve.

Discharge line

blocked.

Check and possibly

correct the

discharge-side dosing

system.

Relief valve incorrectly

set (too low).

Set the relief valve to a

higher opening

pressure.

Diaphragm faulty.

Replace the

diaphragm.

Relief valve dirty.

Clean the relief valve.

Warning

When dosing dangerous media, observe the

corresponding safety precautions!

Risk of chemical burns!

Wear protective clothing (gloves and goggles)

when working on the dosing head, connections

or lines!

Do not allow any chemicals to leak from the

pump. Collect and dispose of all chemicals

correctly!

Warning

The pump housing must only be opened by

personnel authorised by Grundfos!

Repairs must only be carried out by authorised

and qualified personnel!

Switch off the pump and disconnect it from the

power supply before carrying out maintenance

work and repairs!

Caution

For transport or cleaning, the venting cartridge

must be closed.

Before start-up, open the venting cartridge

(pull cap approx. 5 mm).

Caution

In the event of a diaphragm leakage, the dosing

liquid may leak out of the hole in the intermediate

flange between the pump and the dosing head.

The parts inside the housing are protected from

the dosing liquid for a short time (depending on

the type of liquid) by the housing sealing. It is

necessary to check regularly (daily) if liquid is

leaking out of the intermediate flange.

For maximum safety, we recommend the pump

version with diaphragm leakage detection.

Warning

The gear grease must only be changed by

authorised and qualified personnel.

For this purpose, send the pump to Grundfos or

an authorised service workshop.

Caution

If possible, rinse the dosing head, e.g. by

supplying it with water.

T

M

04

83

8

4

09

11

Caution

The O-rings must be correctly placed in the

specified groove.

Observe the flow direction (indicated by an arrow

on the valve)!

DN 20

DN 8

*

*

*