Summary of Contents for OM-TDB/7

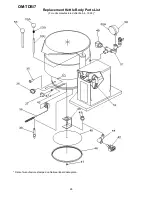

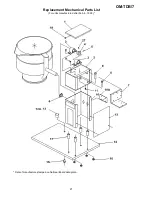

Page 15: ...OM TDB 7 15 ...

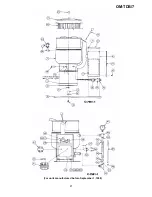

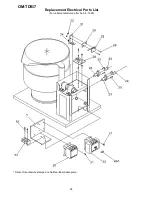

Page 21: ...OM TDB 7 21 For units manufactured before September 1 1998 ...

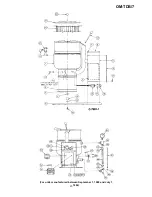

Page 23: ...OM TDB 7 23 For units manufactured between September 1 1988 and July 1 1992 ...

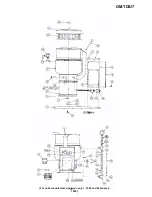

Page 25: ...OM TDB 7 25 For units manufactured between July 1 1992 and February 6 1995 ...

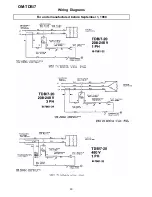

Page 30: ...OM TDB 7 30 Wiring Diagrams For units manufactured before September 1 1988 ...

Page 31: ...OM TDB 7 31 Wiring Diagrams For units manufactured before September 1 1988 ...

Page 32: ...OM TDB 7 32 Wiring Diagrams For units manufactured before September 1 1988 ...

Page 36: ...OM TDB 7 36 Wiring Diagrams For units manufactured after June 1 1990 and before July 1 1992 ...