9

OM-HY-12G/24G

OM-HY-12G/24G

9

B. Initial Start-Up

After the Steamer has been installed, test it to

ensure that the unit is operating correctly.

1. Remove all literature and packing materials

from the interior and exterior of the unit.

2. Make sure the water supply line is open.

3. Make sure that the gas supply line is open

and that the manual knob on the main gas

valve is turned to the “on” position. This

valve is located behind the access panel on

the right side of the unit.

4. Turn on electrical service to the unit. The

unit will not operate without electrical power.

Do not operate during a power failure.

5. The steamer will not operate until the pilot

burner has been ignited. To light the pilot

burner, activate the pilot switch located next

to the main gas valve. When the pilot

ignition sequence has been successfully

completed, a green light - on the pilot switch

- and on the electrical panel (new models)

will glow.

6. The “trial for ignition” period is roughly 90

seconds. If the pilot burner does not light

within about 90 seconds after the switch is

activated, the ignition system automatically

stops gas flow to the pilot burner and stops

the ignition trial. If this happens, turn off the

pilot switch and repeat the trial for ignition.

During the initial start-up, the pilot may

require several trials for ignition until all the

air is bled from the gas piping. Subsequent

start-ups should require only about 5

seconds to achieve pilot ignition.

NOTE: See Automatic Operation of Pilot at

the end of this section.

7. Once the pilot burner flame has been

established (the green light on the pilot

switch or electrical panel (new models) is

on), press the “ON” switch for the desired

steamer cavity. The steam generator will fill

with water.

NOTE: The door MUST be closed for the

main burner to work.

8. When the steam generator has filled with

water, the main burner will ignite

automatically. Within 6-8 minutes the

READY light will come on, indicating that the

water has reached its standby temperature.

When the READY light is displayed, you may

take any one of the following steps:

a. Set the timer to the desired time for

timed steaming.

b. Turn the timer knob to the manual ON

position for continuous steam.

c. Let the unit stay at standby temperature.

WARNING

WHEN YOU OPEN THE DOOR, STAY AWAY

FROM STEAM COMING OUT OF THE UNIT. THE

STEAM CAN CAUSE BURNS.

9. To shut down the unit, press the ON switch

into the off position. The steam generator

will then drain. You may also switch off the

pilot switch to conserve energy.

10. If the HY-12/24G Steamer behaves as

described, the unit is functioning correctly

and ready for use.

Automatic Operation of Pilot

Once the pilot burner is lit, it essentially functions as

a standing pilot. In this state, if the pilot is

accidentally extinguished (by a very strong gust of

wind for example), it will re-ignite automatically. The

unit will completely shut down for a few seconds

while the pilot is re-ignited. Then the unit will come

back on and resume operation in the mode and with

the (running) timer value existing just prior to

shutdown. The pilot switch may be turned off during

“off hours” to conserve energy.

After the unit has been running, if the pilot burner

ever fails to re-ignite automatically within 90

Summary of Contents for HY-12GF

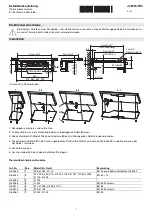

Page 16: ...16 OM HY 12G 24G OM HY 12G 24G 16 Parts List...

Page 18: ...18 OM HY 12G 24G OM HY 12G 24G 18 Schematic Wiring Diagrams...

Page 21: ...NOTES...

Page 22: ...NOTES...

Page 23: ......