Installation

WARNING

INSTALLATION OF THE BRAISING PAN

MUST BE DONE BY A CERTIFIED

ELECTRICIAN OR GROEN AUTHORIZED

REPRESENTATIVE QUALIFIED TO WORK

WITH ELECTRICITY. IMPROPER

INSTALLATION CAN RESULT IN INJURY TO

PERSONNEL AN/OR DAMAGE TO

EQUIPMENT.

Internal wiring for the Braising Pan is supplied

complete. When you receive the unit, it is ready for

connection. A wiring diagram is located inside the

control box on the right side of the pan, as well as in

this manual (pp. 28-33).

Your pan was performance-tested at the factory to

confirm that all controls and heating elements were

functioning correctly.

Installation is as follows:

1. Set the unit in place and level it by turning the

adjustable feet. Crank the pan body to a

completely horizontal position. Check levelness

by placing a spirit level on the bottom of the pan.

The unit must be level to avoid uneven cooking

across the pan.

2. Make a

waterproof

connection with the incoming

power line at the electrical service entrance at the

bottom of the connection box at rear of control

console. A BX connection is

NOT

recommended.

ELECTRICALLY GROUND THE UNIT

at the

proper terminal.

3. Provide the proper electrical supply as specified

on the electrical information plate. Comply with

local codes and the National Electrical Code

ANSI/NFPA 7- latest edition.

4. Use only copper wire, rated at least 75ºC and of

proper gage. See chart on page 8.

5. Standard equipment is shipped ready for 208V,

240V, or 480V, 3-phase operation. Refer to the

wiring diagram located on the inside cover of the

control box and the instructions below for

conversion to single-phase operation.

A jumper wire and “conversion” label are included

with the unit. They can be found in a plastic bag

attached to the trunnion assembly inside the

control box.

CAUTION

BEFORE ANY ELECTRICAL CONVERSION,

VERIFY THAT THE BRANCH CIRCUIT

WIRING IS ADEQUATE TO HANDLE ANY

INCREASE IN AMPERAGE REQUIREMENTS.

R E F E R T O T H E E L E C T R I C A L

SPECIFICATIONS LISTED BELOW.

6.

For conversion from 3-phase to 1-phase

i. Verify that the branch circuit wiring is adequate

for any increased amperage requirements. (See

table on next page)

ii. 1-phase requires two jumper wires. One

jumper wire exists on the terminal block for 3-

phase input. The second jumper wire is located in

a plastic bag inside the control box.

iii. Attach jumper wires to terminal block as per

wiring diagram for 1 phase supply.

iv. Complete “conversion label” (supplied in bag)

and adhere it to the control box near the UL

dataplate.

OM-BMP-E 7

Summary of Contents for Eclipse BPM-30E

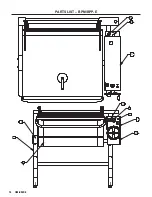

Page 18: ...18 OM BMP E PARTS LIST BPM BPP E 8 9 17 1 2 3 5 13 18 20 21 ...

Page 19: ...OM BMP E 19 PARTS LIST BPM BPP E 4 6 7 10 11 12 19 22 23 14 15 16 ...

Page 24: ...24 OM BMP E WIRING DIAGRAM BPM 30E ...

Page 25: ...OM BMP E 25 WIRING DIAGRAM BPP 30E ...

Page 26: ...26 OM BMP E WIRING DIAGRAM BPM 40E ...

Page 27: ...OM BMP E 27 WIRING DIAGRAM BPP 40E ...

Page 30: ...30 OM BMP E ...

Page 31: ...OM BMP E 31 ...

Page 32: ...32 OM BMP E ...

Page 33: ...NOTES OM BMP E 33 ...

Page 34: ...NOTES 34 OM BMP E ...

Page 35: ...NOTES OM BMP E 35 ...