8

OM-BPM-15/30/40G(C,A) (CE) INTERNATIONAL

MAINTENANCE

WARNING: ELECTRIC POWER ALWAYS SHOULD BE SHUT OFF BEFORE WORK IS DONE

ON INTERNAL COMPONENTS.

WARNING: DISCONNECT ELECTRICAL POWER FROM THE UNIT BEFORE ATTEMPTING

TO GREASE THE TRUNNION BEARINGS.

Your braising pan is designed to require minimum maintenance, but certain parts

may need replacement after prolonged use. After installation, no user adjustment

should be necessary. If a service need arises, only authorized personnel should

perform the work.

Service personnel should check the unit at least once a year. This periodic

maintenance should include inspecting electrical wires and connections, cleaning

the inside of the control console, and possible adjustment of the pilot light. (Units

with standing pilot ignition only) At least twice a year, grease the two trunnion

bearings and worm gear.

We recommend the use of number two grade LGI lithium grease. Add grease

through the zerk fittings on the gear hosing until grease flows out of the bearings

around trunnion shaft. Also, add grease in the gear to cover arc that is in contact

with the worm gear. Clean up excess grease.

A Service Log is provided with the warranty information at the back of this manual.

Each time service is performed on your equipment, enter the date on which

the work was done, what was done, and who did it. Keep the manual with the

equipment for quick and easy reference.

SAFETY PRECAUTIONS

A stop-cock will be fitted in the gas pipe supplying the appliance. The user must

be familiar with its location and operation, and able to turn it off in an emergency.

If there is a smell of gas, immediately turn off the gas, ventilate the area, and call

the gas supplier.

NEVER USE NAKED FLAME TO SEARCH FOR GAS LEAKS.

REPLACEMENT PARTS

To order parts, contact your Authorized Service Agent. Supply the model

designation, serial number, part description, part number, quantity, and when

applicable, voltage and phase.

CONTACT US

If you have questions pertaining to the content in this manual, contact Unified

Brands at 888-994-7636.

TROUBLESHOOTING

This unit is designed to operate smoothly and efficiently if properly maintained.

However, the following is a list of checks to make in the event of a problem.

Wiring diagrams are found at the end of this manual. When in doubt, turn unit

off and call for service at 888-994-7636. If an item on the check list is marked

with (*), it means that the work should be done by a Authorized Service Agent.

WARNING: ELECTRICAL POWER MUST BE SHUT OFF BEFORE WORK IS DONE ON INTERNAL

COMPONENTS. USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE

SUPPLIED BY THE MANUFACTURER OR THEIR AUTHORIZED DISTRIBUTOR

CAN CAUSE INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT

AND WILL VOID ALL WARRANTIES. SERVICE PERFORMED BY OTHER THAN

FACTORY-AUTHORIZED PERSONNEL WILL VOID ALL WARRANTIES.

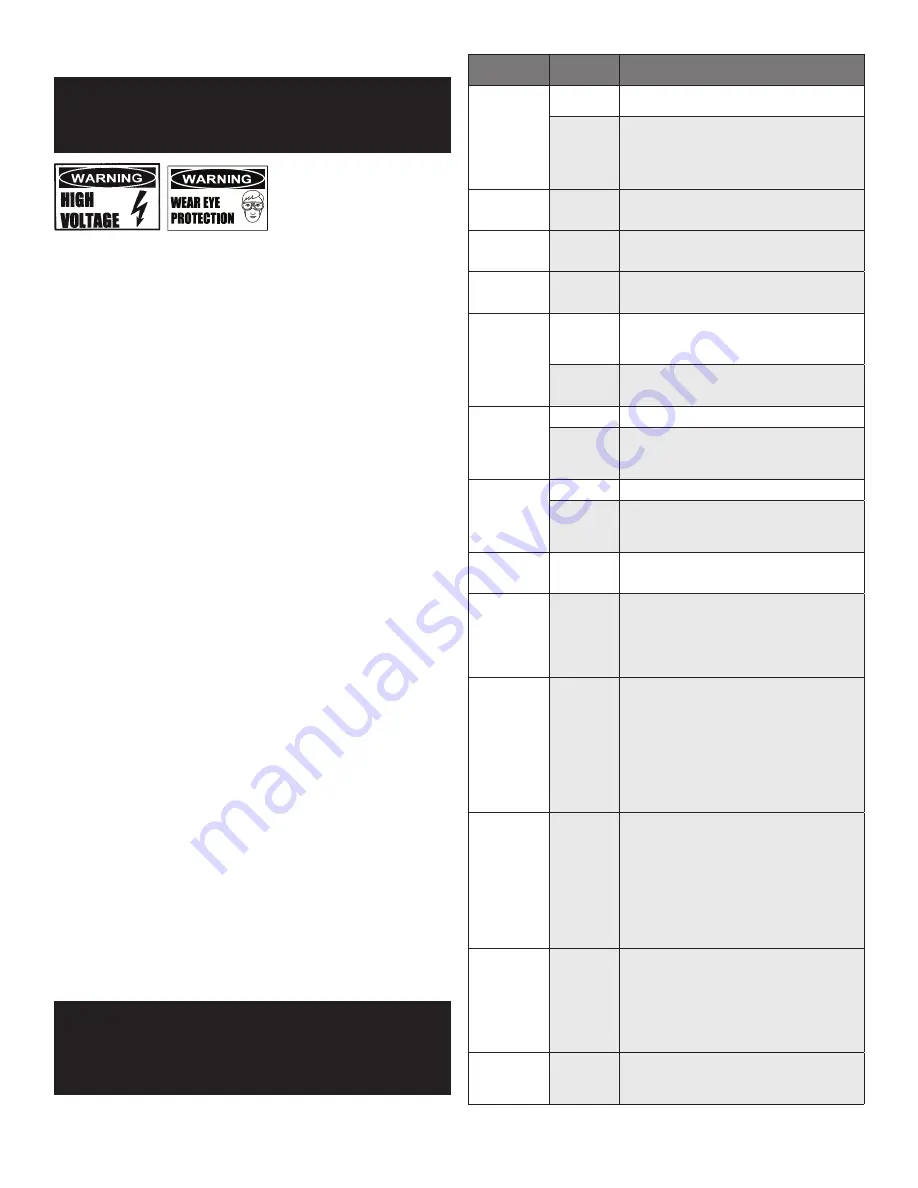

SYMPTOM

WHO

WHAT TO CHECK (X indicates work that should only be

performed by a qualified service representative)

Display not lit

(Advanced only)

User

a.

That power supply is on.

Authorized

Service Rep

Only

b. Fuses, accessible by removing caps on the side of the

control box.

c. For loose or broken wires or damaged RTD probe. X

d. Temperature controller functioning, by listening for a click

when the switch opens or closes and verifying LEDs on back

of board. X

PROB in display

(Advanced only)

Authorized

Service Rep

Only

a. For loose or broken wires or damaged/failed RTD probe. X

b. PCB board malfunction/failure

HI in display

(Advanced only)

Authorized

Service Rep

Only

a. For loose or broken wires or damaged/failed RTD probe. X

b. PCB board malfunction/failure

Pan is hard to tilt

Authorized

Service Rep

Only

a. Gears or foreign materials, lubrication, and alignment. X

b. Broken tilt or worm gears. X

Burners will not

light

User

a. That the main gas supply valve is open (handle is in line with

the gas pipe)

b. Gas supply to the braising pan is at specified pressure.

c. That the pan body is horizontal.

Authorized

Service Rep

Only

d. Temperature controller operation. The contacts should click

when the dial is rotated to settings above and below the

temperature of the pan. X

Pan continues

to heat

after it reaches

desired

temperature

User

a. Temperature controller dial setting and display.

Authorized

Service Rep

Only

b. Temperature controller calibration and offsets. X

c. Temperature controller operation. The thermostat should

click when the dial is rotated to settings above and below

the temperature of the pan. X

Pan stops heating

before reaching

desired

temperature

User

a. Temperature controller dial setting and display.

Authorized

Service Rep

Only

b. Temperature controller calibration and offsets. X

c. Temperature controller operation. The contacts should click

when the dial is rotated to settings above and below the

temperature of the pan. X

Pan heats

unevenly

User

a. That the pan body is horizontal.

b. That the pan is preheated properly in accordance with the

instructions in the Operation section of this manual.

System does not

produce a spark

Authorized

Service Rep

Only

a. Controller and ensure that it is energized X

b. AC voltage between terminals on secondary side of

transformer. If it is not 24 Volt, replace the transformer X

c. That the high tension cable is in good condition. If cracked or

brittle, replace.

X

d. Pilot electric ceramic for crack or break. X

e. Pilot spark gap. Regap. X

Spark is present

but the pilot will

not light

Authorized

Service Rep

Only

a. That the pilot valve is securely connected to terminals. X

b. For 24 VAC at terminals PV and to ground.

If

24V is not present, replace the ignition control module. X

c. That gas pressure is at least 3.5” W.C.(8.7millibars). X

d. For gas at the pilot. If it is not flowing:

(1) Check the pilot gas line for kinks and obstructions. X

(2) Clean orifice, if necessary. X

(3) Check solenoid operation pilot valve on gas valve.

Repair or replace as necessary. X

e. That the pilot spark gap is located in the pilot gas stream. If

not, adjust or replace the pilot burner. X

f. For drafts. Shield the pilot burner, if necessary. X

Pilot lights, but

main burner will

not come on and

spark does not

stay on

Authorized

Service Rep

Only

a. Check controller to see that it is closed at temperature

setting higher than that of the current pan temperature.

X

b. For 24 V between terminals MV and to ground.

If

24V is not present, replace the ignition control module.

X

c. That gas pressure is at least 3.5” W.C.(8.7millibars). X

d.

Electrical connections of the main valve to terminals, to

assure that they are securely attached. Check solenoid

operation for main valve on gas valve. Repair or replace

as necessary. X

e. That secondary thermostat switch is closed.X

Pilot lights, but

main burner will

not come on, the

spark stays on

Authorized

Service Rep

Only

a. Check for improper grounding.

If necessary,

repair with high temperature wire. X

b. Pilot burner ceramic insulator for cracks. X

c. That high tension cable is not grounded out. If it is,

correct the ground-out condition or the pilot burner. X

d. For proper gas pressure. X

e. Clean pilot assembly, or replace if necessary. X

f. Tighten all mechanical and electrical connections. X

g. Replace ignition control module.

X

Main burner

comes on but will

not stay on.

Authorized

Service Rep

Only

a. Check burner ground for bad wire or connection.

Replace if necessary with high temperature wire. X

b. Check for low gas supply pressure. If necessary, replace

ignition control module. X