-30-

Model G0825 (Mfd. Since 02/17)

Review the troubleshooting and procedures in this section if a problem develops with your machine. If

you need replacement parts or additional help with a procedure, call our Technical Support.

Note: Please

gather the serial number and manufacture date of your machine before calling.

SECTION 7: SERVICE

Troubleshooting

Motor & Electrical

Symptom

Possible Cause

Possible Solution

Machine does not

start, or a circuit

breaker trips

immediately upon

startup.

1. Plug/receptacle at fault/wired wrong.

2. Incorrect power supply voltage/circuit size.

3. Power supply circuit breaker tripped/fuse

blown.

4. Glue pot has not reached operating

temperature.

5. Blown fuse on machine.

6. Master power switch off/at fault.

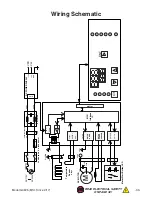

7. Motor wires connected incorrectly.

8. Wiring open/has high resistance.

9. Circuit board at fault.

10. Motor at fault.

1. Test for good contacts; correct wiring.

2. Ensure correct power supply voltage/circuit size.

3. Ensure circuit is sized correctly and free of shorts;

reset circuit breaker/replace fuse.

4. Allow glue pot to reach 155°C.

5. Check/replace blown fuses.

6. Turn switch ON; test/replace switch.

7. Correct motor wiring connections.

8. Check/fix broken, disconnected, or corroded wires.

9. Inspect/replace.

10. Test/repair/replace.

Motor stalls or is

underpowered.

1. Motor overheated.

2. Chain slipping; oil/grease on belt(s).

3. Motor(s) wired incorrectly.

4. Plug/receptacle at fault.

5. Pulley/sprocket slipping on shaft.

1. Allow motor to cool.

2. Clean/tension/replace chain (

Pages 29).

3. Wire motor(s) correctly.

4. Test for good contacts/correct wiring.

5. Replace loose pulley/shaft.

Machine has

vibration or noisy

operation.

1. Motor or component loose.

2. Sprocket loose.

3. Machine incorrectly mounted to work table.

4. Motor shaft bent.

1. Inspect/replace damaged bolts/nuts, and retighten

with thread-locking fluid.

2. Re-align/replace shaft and pulley set screw.

3. Tighten mounting bolts; relocate/shim machine.

4. Test with dial indicator and replace motor.

Control panel

readout shows error

code.

1. Control panel reads:

Er1.

2. Control panel reads:

Er2.

3. Control panel reads:

Er3

4. Control panel reads:

Er4

1. Indicates voltage error. Check input voltage to

ensure it is adequate for edgebander.

2. Indicates motor error. Contact Technical Support for

assistance.

3. Indicates heating element error. Signals when

heating element exceeds 220ºC. Turn machine

OFF

and disconnect from power; call Technical Support

for assistance.

4. Indicates temperature-detecting wire error. Turn

machine

OFF and disconnect from power; call

Technical Support for assistance.

Summary of Contents for G0825

Page 44: ......