-20-

Model G0825 (Mfd. Since 02/17)

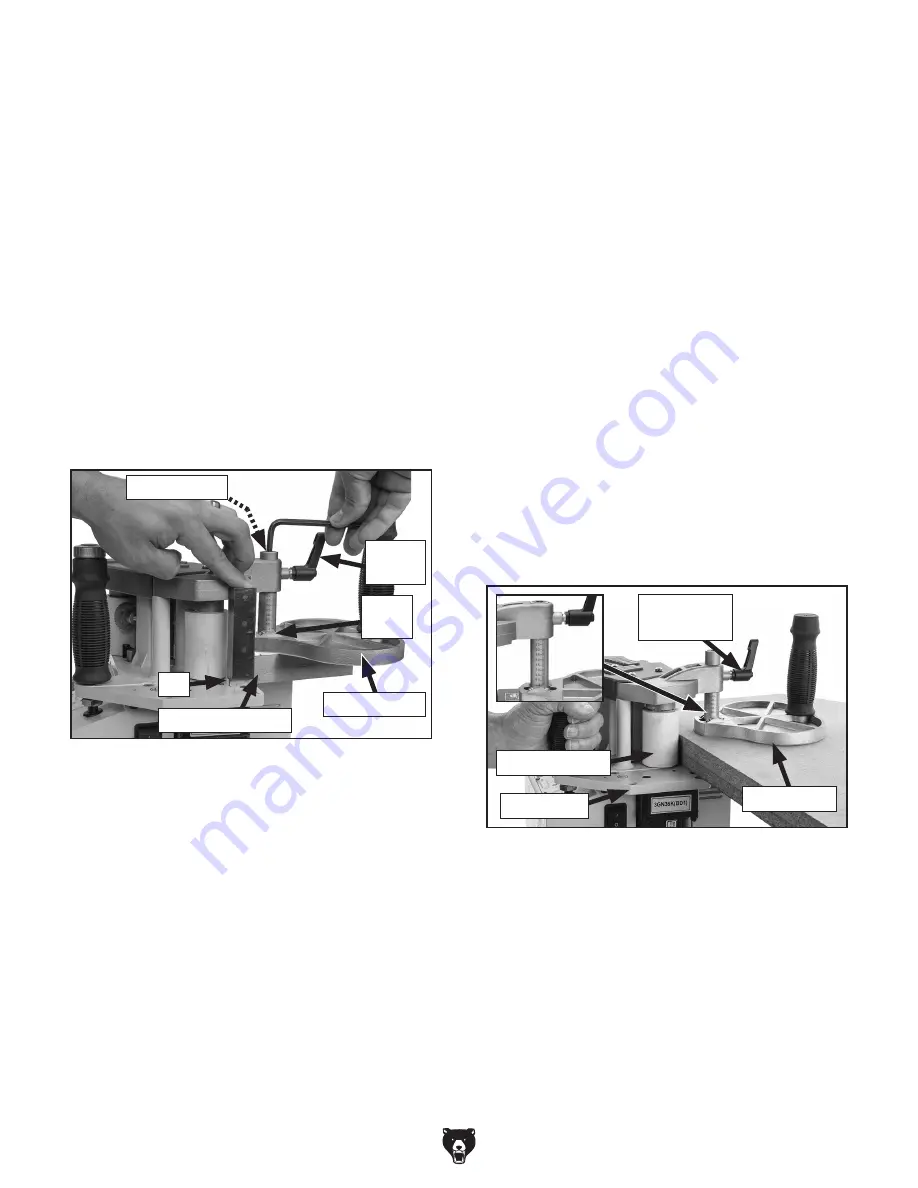

The guide plate must be adjusted to allow top

edge of edgebanding tape to align flush to top of

workpiece. Use the guide-plate height scale (dis-

played in millimeters) to set the guide plate.

Note: For smooth feeding, add a few millime-

ters to your measurement to allow clearance for

adjustments in

Step 3. This can easily be done

by putting an appropriately thick piece of paper on

workpiece when setting guide plate.

Note: Always ensure guide plate lock is properly

secured before operation.

To set height of guide plate:

1. Place guide plate on top of workpiece, then

move edgebander toward workpiece until

feed roller and baseplate contact workpiece

edge, as shown in

Figure 17.

Note: If necessary, raise or lower the

guide plate to allow outfeed rollers to reach

workpiece.

2. Retighten guide-plate lock lever to secure

setting.

Guide Plate

Lock Lever

Figure 17. Guide plate adjusted for workpiece

height.

Guide Plate

Outfeed Roller

Base Plate

Setting Guide Plate Height

4. Tighten lock screw and re-check to confirm

setting.

5. Calibrate angle scale pointer/scale plate to 0º

by loosening Phillips head screws, adjusting

scale plate, then retightening screws.

To set guide plate angle 90º to feed roller:

1. With one hand, place precision square even

with face of outfeed roller and across outfeed

side of base plate (see

Figure 16).

2. With free hand, loosen guide-plate lock lever

(see

Figure 16), and lower guide plate evenly

onto precision square, then retighten lock

lever.

3. Loosen lock screw (see Figure 16), and

adjust guide plate angle until it sits flush

along precision square.

Figure 16. Squaring guide plate.

Lock

Lever

Precision Square

Lock Screw

Guide Plate

90º

Angle

Scale

Tools Needed

Qty

Precision Square ............................................... 1

Hex Wrench 6mm .............................................. 1

Setting Guide Plate Angle

Summary of Contents for G0825

Page 44: ......