-32-

Model G0792 (Mfd. Since 12/15)

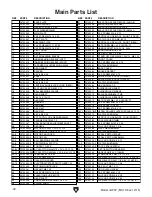

Main Parts List

REF

PART #

DESCRIPTION

REF PART #

DESCRIPTION

1

P0792001

BASE PLATE

47

P0792047

ELEVATION SPACER BLOCK (LARGE)

2

P0792002

STAND W/DOOR

48

P0792048

ELEVATION LEVER SHAFT

3

P0792003

HEX BOLT M10-1.5 X 30

49

P0792049

ELEVATION SUPPORT BLOCK

4

P0792004

FLAT WASHER 10MM

50

P0792050

ELEVATION SPACER BLOCK (SMALL)

5

P0792005

MAIN PLATE

51

P0792051

CAP SCREW M5-.8 X 12

6

P0792006

CAP SCREW M10-1.5 X 30

52

P0792052

VERTICAL SLIDE BLOCK, SHORT (FRONT)

7

P0792007

PIVOT PLATE

53

P0792053

FLAT HD CAP SCR M5-.8 X 10

8

P0792008

GEARING PLATE

54

P0792054

VERTICAL SLIDE BLOCK, SHORT (REAR)

9

P0792009

CAP SCREW M12-1.75 X 35

55

P0792055

SET SCREW M8-1.25 X 25 DOG-PT

10

P0792010

CAP SCREW M10-1.5 X 35

56

P0792056

HANDLE SHAFT M16-2 X 16, 395L

11

P0792011

PIVOT SHAFT

57

P0792057

ROUND KNOB M16-2 SS

12

P0792012

HINGE

58

P0792058

HEX BOLT M10-1.5 X 60

14

P0792014

OUTER BEARING SLEEVE

59

P0792059

STAND-OFF HEX MF M8-1.25 X 14, M8-1.25

15

P0792015

INNER BEARING SLEEVE (LEFT)

60

P0792060

FRONT COVER

16

P0792016

INNER BEARING SLEEVE (RIGHT)

61

P0792061

CAP SCREW M8-1.25 X 16

17

P0792017

TAPERED ROLLER BEARING 30206

62

P0792062

FLAT WASHER 8MM

18

P0792018

GEAR SHAFT

63

P0792063

BACK COVER

19

P0792019

SPACER

64

P0792064

ANGLE BRACKET

20

P0792020

KEY 8 X 8 X 45

65

P0792065

CAP SCREW M6-1 X 10

21

P0792021

SHAFT

66

P0792066

ROLLER FLAT 3-13/16" (LOWER)

22

P0792022

KEY 8 X 8 X 18

67

P0792067

ROLLER FLAT 3-13/16" (UPPER)

23

P0792023

KEY 8 X 8 X 40

68

P0792068

FLAT WASHER 20MM

24

P0792024

VERTICAL SLIDE BLOCK, LONG (REAR)

69

P0792069

HEX NUT M20-1.5

25

P0792025

FLAT HD CAP SCR M6-1 X 12

70

P0792070

GUIDE ROLLER SHAFT

26

P0792026

BALL BEARING 6205-2RS

71

P0792071

GUIDE ROLLER SLEEVE

27

P0792027

GEAR SHAFT

72

P0792072

BALL BEARING 6001-2RS

28

P0792028

KEY 10 X 10 X 19

73

P0792073

GUIDE ROLLER BRACKET

29

P0792029

GEAR 33T

74

P0792074

SET SCREW M8-1.25 X 20 DOG-PT

30

P0792030

BUSHING

75

P0792075

CAP SCREW M8-1.25 X 30

31

P0792031

GEAR 68T

76

P0792076

DRIVESHAFT COVER

32

P0792032

GEAR 24T

77

P0792077

CAP SCREW M5-.8 X 10

33

P0792033

GEAR 55T

78V2 P0792078V2 UPPER ROLLER PLATE W/SCALE V2.12.15

34

P0792034

KEY 8 X 8 X 56

79

P0792079

FLAT WASHER 5MM

35

P0792035

EXT TOOTH LOCK WASHER 30MM

81

P0792081

VERTICAL SLIDE BLOCK, LONG (FRONT)

36

P0792036

SPANNER NUT M30-1.5

82

P0792082

LOCK WASHER 10MM

37

P0792037

ROLLER GUIDE ADJUSTMENT SHAFT

83

P0792083

CAP SCREW M10-1.5 X 30

38

P0792038

GEARBOX

84

P0792084

PHLP HD SCR M4-.7 X 8

39V2

P0792039V2

MOTOR 2HP 220V 1-PH V2.12.15

85

P0792085

WAVY WASHER 4MM

39-2V2 P0792039-2V2 MOTOR JUNCTION BOX V2.12.15

86

P0792086

FLAT WASHER 4MM

39-3

P0792039-3

MOTOR FAN COVER

91

P0792091

PEDAL SWITCH STAND

39-4

P0792039-4

MOTOR FAN

92

P0792092

PEDAL SWITCH ASSEMBLY

39-5

P0792039-5

BALL BEARING 6205-2RS

92-1

P0792092-1 PHLP HD SCR M3-.5 X 12

39-6

P0792039-6

CENTRIFUGAL SWITCH

92-2

P0792092-2 FLAT WASHER 3MM

39-7

P0792039-7

CONTACT PLATE

92-3

P0792092-3 FOOT PEDAL SWITCH

39-8V2 P0792039-8V2 S CAPACITOR 400M 275V 2 X 4 V2.12.15

93

P0792093

E-STOP BUTTON ZB2-BE102

39-9V2 P0792039-9V2 R CAPACITOR 40M 450V 2 X 3-3/4 V2.12.15

94

P0792094

HANDLE GRIP 25 X 128MM

39-10

P0792039-10 TERMINAL BLOCK 3P

95

P0792095

STRAIN RELIEF M20-1.5 TYPE-5

39-11

P0792039-11 TAP SCREW M3 X 12

96

P0792096

FLEXIBLE CONDUIT 7/8" X 3-1/2" (PLASTIC)

39-12

P0792039-12 CAPACITOR COVER

97

P0792097

FLEXIBLE CONDUIT 7/8" X 63" (PLASTIC)

39-13

P0792039-13 ELECTRONIC START SWITCH ESS1-40

98

P0792098

PHLP HD SCR M4-.7 X 28

40

P0792040

MOTOR MOUNT BLOCK

99

P0792099

HEX BOLT M6-1 X 12

41

P0792041

HEX NUT M8-1.25

100

P0792100

DOOR LATCH W/KEY

42

P0792042

CAP SCREW M10-1.5 X 25

101

P0792101

CAP SCREW M6-1 X 16

43

P0792043

ELEVATION SLIDE BLOCK

102

P0792102

PHLP HD SCR M5-.8 X 26

44

P0792044

GEAR SHAFT

103

P0792103

PHLP HD SCR M5-.8 X 95

45

P0792045

COMPRESSION SPRING 10.5 X 15

104

P0792104

FLEXIBLE CONDUIT 7/8" X 24" (PLASTIC)

46

P0792046

SPRING SHAFT

Summary of Contents for G0792

Page 44: ......