Model G0792 (Mfd. Since 12/15)

-21-

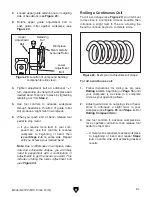

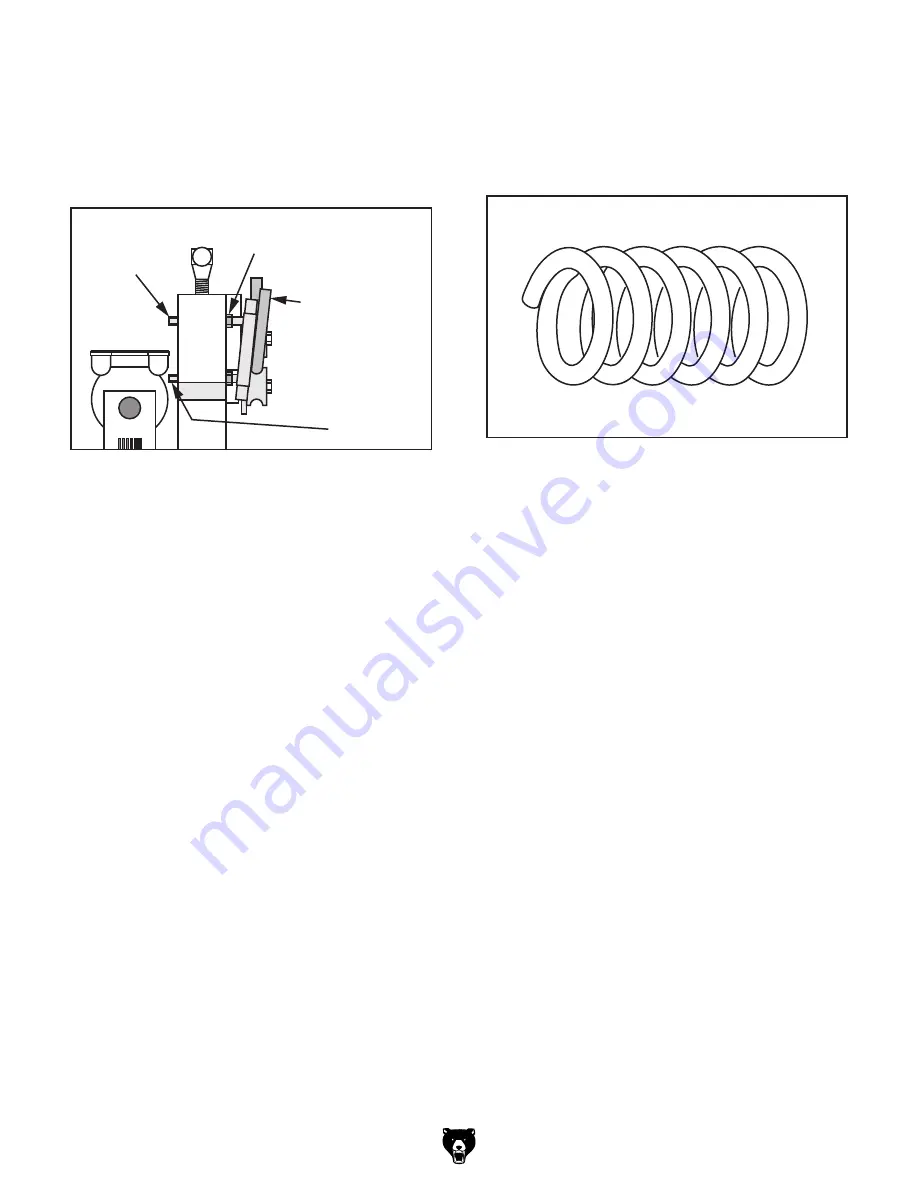

Rolling a Continuous Coil

To roll a coil shape (see

Figure 24) you first must

roll as close to a complete circle as possible, then

introduce a slight twist to the arc, allowing the

bend to continue beyond a complete circle.

4. Tighten adjustment bolt an additional

1

⁄

4

–1

turn, depending on strength of workpiece and

desired bend, then lock in place by tightening

retaining nut from

Step 2.

5. Use foot controls to advance workpiece

through headstock. Position of guide roller

will produce a slight twist in workpiece.

6. When you reach end of bend, release foot

pedal to stop motor.

— If you require more twist in your com-

pound arc, use foot controls to reverse

workpiece to beginning of bend, then

repeat

Steps 2–6 on same side. Repeat

until you achieve your desired bend.

Note: Due to differences in workpiece mate-

rials and achievable shapes, you will likely

need to experiment with a combination of

adjustments to get the results you want. This

includes rotating the lower adjustment bolt

(see

Figure 23).

Upper

Adjustment

Bolt

Lower

Adjustment

Bolt

Workpiece

Bent Laterally

by Guide Roller

Retaining

Nut

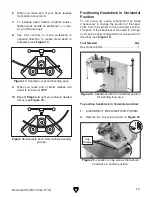

Figure 23. Location of compound bending

components (side view).

2. Loosen upper guide retaining nut on outgoing

side of headstock (see

Figure 23).

3. Rotate upper guide adjustment bolt to

push guide roller against workpiece (see

Figure 23).

Figure 24. Example of achievable coil shape.

To roll a continuous coil:

1. Follow instructions for rolling an arc (see

Rolling an Arc, beginning on Page 18) until

your workpiece is as close to a complete

circle as your operation allows.

2. Adjust guide roller on outgoing side of head-

stock to introduce a slight twist in your

workpiece (see

Figure 23 and Steps 2–4 of

Rolling Compound Arc).

3. Use foot controls to advance workpiece as

far as operation will allow, then release foot

pedal to stop motor.

— If more twist is required, reverse workpiece

to beginning of bend and repeat

Steps

2–3 on same side until achieving desired

results.

Summary of Contents for G0792

Page 44: ......