-70-

Model G0773 (Mfd. Since 4/17)

Tensioning &

Replacing V-Belts

V-belts stretch and wear with use, so it is impor-

tant that tension is routinely checked and adjusted

as needed. Improperly tensioned V-belts will slip

or poorly transmit power from the motor. We rec-

ommend checking the tension on a monthly basis

to ensure optimal power transmission. Replace

the V-belt if it becomes cracked, frayed, or glazed.

Keep belts and pulleys clear of exposure to oil,

grease, or cutting fluids that will cause them to

slip.

Tool Needed

Qty

Hex Wrench 4mm .............................................. 1

Pulley

Deflection

Pulley

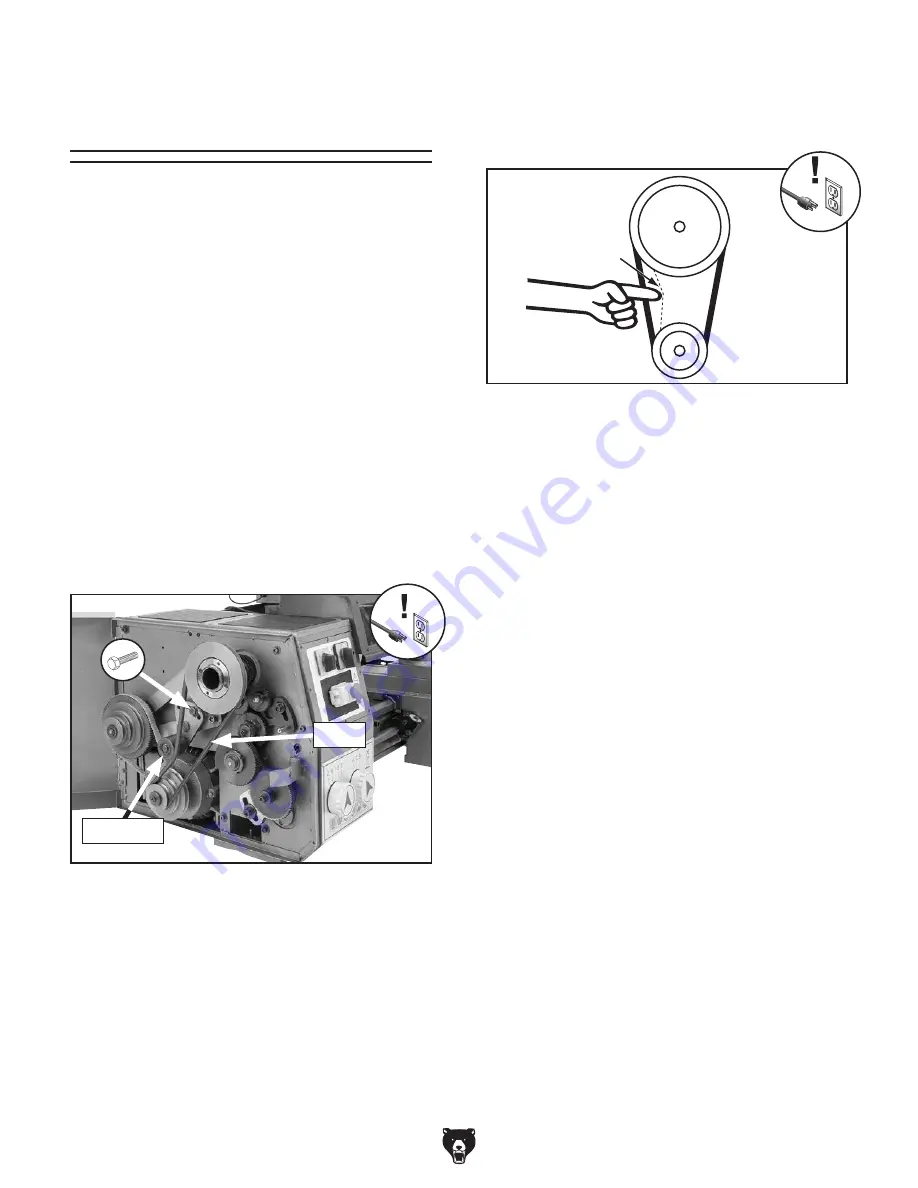

Figure 120. Correct V-belt deflection.

1

⁄

8

"

The V-belt is correctly tensioned when there

is approximately

1

⁄

8

" deflection when pushed

with moderate pressure between the pulleys,

as shown in

Figure 120.

—If there is more than

1

⁄

8

" deflection, adjust

tension until it is correct.

5. Close end cover.

Replacing V-Belts

1. DISCONNECT MACHINE FROM POWER!

2. Open end cover.

3. Loosen tensioner bolt (see Figure 119) to

relieve tension on V-belt.

4. Carefully roll V-belt off of pulleys.

5. Install new V-belt, then tension as described

in

Tensioning V-Belts.

Tensioning V-Belts

1. DISCONNECT MACHINE FROM POWER!

2. Open end cover.

3. Loosen tensioner hex bolt (see Figure 119).

Figure 119. Tensioner bolt and V-belt.

Tensioner

V-Belt

4. Pivot tensioner (see Figure 119) against

V-belt to increase belt tension, then re-tighten

tensioner hex bolt.