29

TROUBLESHOOTING

FASTENER DRIVING PROBLEMS

Tool leaks air.

Check for source of leak, and tighten fttings

and screws as required. Discontinue using

tool if air leaks at trigger area or from cap

exhaust. Contact your dealer.

Tool operates, but no

fastener is driven.

Tool won’t operate -

nail jammed in tool

nose, preventing tool

from operating.

Remove jammed fastener. Check magazine

for incorrect, bent, or loose fasteners, and

discard. Reload using Grip-Rite nails.

®

Check magazine for jammed fastener. Clear

jam and reload magazine. Check nail strip for

smooth feeding in magazine.

TOOL CHECKS

Keep your nailer in top working condition by checking it daily. See your

Grip-Rite dealer for service if part or operating problems are found.

®

Never use a malfunctioning tool - it could result in serious injury.

Workpiece Contact & Trigger

Check workpiece contact for proper operation before each use.

Workpiece contact must move freely and return to extended position

when lifted from workpiece. Trigger must operate freely.

Daily Inspection

• Check for broken, damaged, or excessively worn parts, and repair

or replace as needed.

• Check for air leaks at trigger, cap, and nose. Disconnect tool

from air supply immediately if leaks are present, and see dealer

for service.

• Make sure all screws are tightened securely.

Summary of Contents for GRTFC83

Page 10: ...10 DESCRIPTION GRTFR83 L TOOL PARTS 1 2 3 8 6 7 11 10 9 5 4 ...

Page 12: ...12 DESCRIPTION GRTFC83 TOOL PARTS 1 2 3 7 5 6 10 9 8 4 GRTFC83 ...

Page 14: ...14 DESCRIPTION GRTFW83 TOOL PARTS 1 2 3 7 5 6 10 9 8 4 GRTFW83 ...

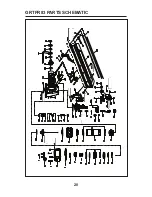

Page 20: ...GRTFR83 PARTS SCHEMATIC 20 ...

Page 22: ...22 GRTFR83L PARTS SCHEMATIC ...

Page 24: ...24 GRTFC83 PARTS SCHEMATIC ...

Page 26: ...26 GRTFW83 PARTS SCHEMATIC ...

Page 32: ...22 USE GENUINE GRIP RITE FASTENERS FOR BEST PERFORMANCE GRTF83MAN 9 10 www grip rite com ...