7

WEAR SAFETY GLASSES

Always wear safety glasses with side shields that meet ANSI

Z87.1 requirements when operating the tool. Make sure all

others in work area wear safety glasses.

WEAR HEARING PROTECTION

Wear hearing protection to protect your hearing from noise.

Prolonged exposure to loud noise can result in hearing loss.

NEVER OPERATE THE TOOL WITH OXYGEN OR OTHER

BOTTLED GASES

Oxygen and other reactive or high-pressure bottled gases can

cause the tool to explode. Use clean, dry regulated

compressed air from a properly operating air compressor.

DO NOT EXCEED MAXIMUM RECOMMENDED OPERATING

AIR PRESSURE OF 120 PSI /8.6 Bar.

Exceeding the maximum recommended air pressure can

cause the tool housing to burst, or cause premature failure of

components.

NEVER CONNECT THE TOOL TO AN AIR SUPPLY THAT

HAS THE POTENTIAL TO EXCEED 180 PSI/12.4 Bar.

Using a regulated air supply with a line or tank pressure

greater than 180 psi can cause the tool to burst if the air line

regulator fails suddenly.

USE AN AIR HOSE RATED FOR 180 PSI/12.4 Bar OR

GREATER

Always use air hose rated to handle 180 psi or the maximum

potential pressure of the air supply.

ONLY USE A RELIEVING-TYPE AIR COUPLING IN THE

TOOL AIR INLET OPENING

Use of a non-relieving air coupling on the tool can trap air

inside the tool housing, and allow the tool to drive a fastener

SAFETY

SAFETY INSTRUCTIONS

even after the air hose has been disconnected.

120 psi

4.9 bar

70 psi

8.3 bar

Summary of Contents for GRTFC83

Page 10: ...10 DESCRIPTION GRTFR83 L TOOL PARTS 1 2 3 8 6 7 11 10 9 5 4 ...

Page 12: ...12 DESCRIPTION GRTFC83 TOOL PARTS 1 2 3 7 5 6 10 9 8 4 GRTFC83 ...

Page 14: ...14 DESCRIPTION GRTFW83 TOOL PARTS 1 2 3 7 5 6 10 9 8 4 GRTFW83 ...

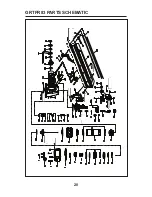

Page 20: ...GRTFR83 PARTS SCHEMATIC 20 ...

Page 22: ...22 GRTFR83L PARTS SCHEMATIC ...

Page 24: ...24 GRTFC83 PARTS SCHEMATIC ...

Page 26: ...26 GRTFW83 PARTS SCHEMATIC ...

Page 32: ...22 USE GENUINE GRIP RITE FASTENERS FOR BEST PERFORMANCE GRTF83MAN 9 10 www grip rite com ...