9. AUTHORISED USAGE

9.1 MATERIALS

This boring machine has been designed and manufactured to bore holes in the following materials:

-

heart-wood

-

M.D.F.

-

Chip-wood boards, laminated wood, ennobled wood etc.

Maximum board thickness is 82 mm with maximum size indicated in paragraph 8.3

Other materials than the ones indicated above can be worked only after having received written ap-

proval by machine manufacturer. In particular it is forbidden to work materials containing toxic sub-

stances or substances that are hazardous for operator’s health and safety. It is also forbidden to bore

metals or substances that might impair the machine good performance of might cause fire or explosions.

-

Any modification to the machine is forbidden without the written approval by the machine manufac-

turer.

-

It is forbidden to tamper with the machine safety devices

9.2 IMPROPER USAGE

Any operation that does not comply with the indications given in this manual is to be regarded as im-

proper usage.

Moreover:

WE ADVISE YOU NOT TO: lay tools against or on the machine during machine installation, usage or

maintenance operations for any reason whatsoever.

WE ADVISE YOU NOT TO: get on the machine or on any of its parts.

The manufacturer cannot be held responsible for any damage caused to people, animals, or objects

resulting from improper usage of the machine.

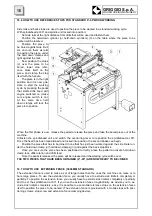

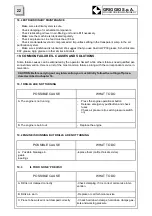

8.5 TABLE SIZE

Version GF 21 900 X 380 mm

Version GF 27 1050 X 380 mm

Version GF 35 1360 X 410 mm

8.6 INTERAXIAL DISTANCE BETWEEN SPINDLES

The interaxial distance between spindles is 32 mm.

8.7 NUMBER OF SPINDLES

Version GF 21 21 spindles

Version GF 27 27 spindles

Version GF 35 35 spindles

8.8 INTERAXIAL DISTANCE BETWEEN FIRST AND LAST SPINDLE

Version GF 21 640 mm

Version GF 27 832 mm

Version GF 35 1088 mm

8.9 SPINDLE REVOLUTIONS

Spindles revolutions are …2800 r.p.m. at 50 Hz

Spindles revolutions are …3300 r.p.m. at 60 Hz

8.10 MAXIMUM BORING DEPTH

Maximum boring depth is …100 mm.

8.11 WORKING PRESSURE

Working pressure is … 6/7 bar

8.12 AIR CONSUMPTION

Air consumption is …10L/Cycle

9

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Summary of Contents for GF 21

Page 2: ......

Page 4: ......

Page 23: ...16 10 WOODWORKING EXAMPLES 19 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 24: ...GRIGGIO S p A WOODWORKING MACHINERY 20 ...

Page 33: ...29 GRIGGIO S p A WOODWORKING MACHINERY 26 SPARE PARTS CATALOGUE ...

Page 35: ...TABLE 1 FRAME 31 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 37: ...TABLE 2 MACHINE TABLE 33 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 39: ...TABLE 3 RACK 35 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 41: ...TABLE 4 LIMITERS 37 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 43: ...TABLE 5 SPINDLES UNIT 39 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 45: ...TABLE 6 HOLD DOWN CLAMPS FRAME 41 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 47: ...TABLE 7 BACK STOP 43 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 49: ...TABLE 8 HOLD DOWN CLAMPS 45 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 51: ...TABLE 9 SPINDLEHEAD 47 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 53: ...TABLE 10 EXTENSION FENCE 49 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 55: ......