IN-GE-RPCXXXBAC-01-02 03/19

Page 1

Copyright © Greystone Energy Systems, Inc. All Rights Reserved Phone: +1 506 853 3057 Web: www.greystoneenergy.com

INTRODUCTION

The room pressure transmitter is used to measure differential pressure

in the range of 0.125 to 1"wc or 30 to 250 Pa. It combines precision high

sensitivity silicon sensing capabilities and the latest ASIC technology

to substantially reduce offset errors due to changes in temperature,

stability to warm up, long term instability and position sensitivity. It

is ideal for monitoring pressure for air or other clean inert gas. The

device has an on-board auto-zero function, backlit LCD and alarm

function with silence switch plus a native BACnet® RS-485 MS/TP

network connection.

BEFORE INSTALLATION

Read these instructions carefully before installing and commissioning the room pressure transmitter.

Failure to follow these instructions may result in product damage. Do not use in an explosive or hazardous

environment, with combustible or flammable gases, as a safety or emergency top device or in any other

application where failure of the product could result in personal injury. Take electrostatic discharge

precautions during installation.

Do not exceed the device ratings.

MOUNTING

The room pressure transmitter mounts directly on a wall or onto an electrical wall box. For the most

accurate results, units should be mounted on an inside wall to a wall box five feet from the floor. Do not

mount the sensor near doors, opening windows, supply air diffusers, or other known air disturbances.

Avoid areas where the sensor is exposed to vibrations or rapid temperature changes. To prevent erroneous

readings due to air disturbances within the wall cavity, seal the conduit leading to the junction box.

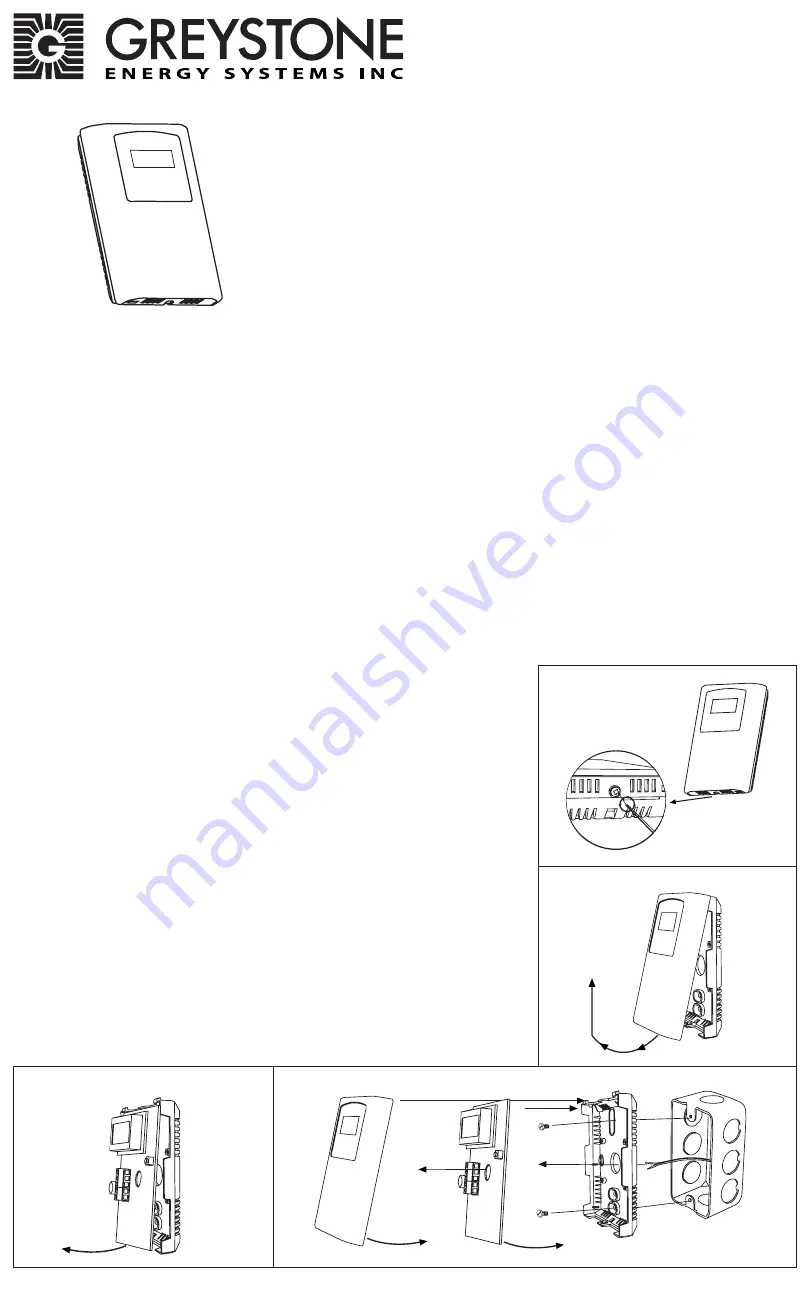

The cover is hooked to the base at the top edge and must be removed from the bottom edge first. Use

a small Phillips screwdriver to loosen the security screw as shown in Figure 1. (Complete removal is not

required). Use a screw driver to carefully pry each bottom corner if necessary. Tip the cover away from the

base and sit it aside as shown in Figure 2.

The PCB must be removed from the base to access the mounting

holes. Follow usual anti-static procedures when handling the PCB and

be careful not to touch the sensors. The PCB is removed by pressing

the enclosure base to unsnap the latch near the bottom edge, then

the PCB can be lifted out of the base as shown in Figure 3.

Set the PCB aside until the base is mounted on the wall. For added

protection, place the PCB in the supplied anti-static bag.

Mount the base by screwing it to an electrical box or directly to the

wall as shown in Figure 4.

After the base is screwed to an electrical box or the wall using the

appropriate holes, remove the PCB from the anti-static bag, feed

connection wires through center hole and place the top of the PCB

into the PCB holders on the backplate and snap the bottom of the

PCB into place as shown in Figure 4.

Make wire connections as per the Wiring Illustrations on Page 2 and

install decorative cover by placing the top of the cover into the cover

holder on the top of the backplate and snapping the bottom into

place as shown in Figure 4. Tighten security screw with a screwdriver.

Network Room

Pressure Transmitter

RPC Series - Installation Instructions

Figure 1

Figure 4

Figure 3

Figure 2

Cover

PCB

Backplate