Page 2

WIRING

•

Use 18-24 AWG shielded wiring for all connections. Do not locate the device wires in the same conduit with wiring used to supply inductive

loads such as motors. Make all connections in accordance with national and local codes.

•

Pull at least six inches of wire into the enclosure, then complete the wiring connection according to the wiring diagrams below.

•

Thermistors are a 2 wire hook up and are not polarity sensitive. See Figure 7.

•

RTD’s that are 3 wire hook up, see Figure 8.

SPECIFICATIONS

:

Sensor Type:

..........................................

Various thermistors or RTD

Sensor Accuracy: .................................

RTD Class A:

±0.15°C (±0.27°F) @ 0°C (32°F)

RTD 1/3 DIN:

±0.1°C (±0.18°F) @ 0°C (32°F)

RTD 1/10 DIN:

±0.03°C (±0.054°F) @ 0°C (32°F)

NTC Thermistor Type 39:

±0.05°C (±0.09°F), 0 to 70°C (32 to 158°F)

NTC Thermistor Type 55:

±0.03°C (±0.054°F), 0 to 70°C (32 to 158°F)

NTC Thermistor Type 40/46:

±0.1°C (±0.18°F), 0 to 70°C (32 to 158°F)

Probe Sensing Range: ......................

RTD:

-20 to 100°C (-4 to 212°F)

Thermistors:

-40 to 100°C (-40 to 212°F)

Ambient Operating Range: ............-40 to 50°C (-40 to 122°F), 5 to 95 %RH non-condensing

Wire Material: ........................................

RTD:

FT-4, 22 AWG, 3 Wire

Thermistor:

PVC insulated, parallel bonded, 22 AWG, 2 Wire

Probe Material: .....................................304 Series stainless steel

Probe Diameter:...................................6 mm (0.236")

Standard lengths: ................................50, 100, 150, 200, 300, and 450 mm (2", 4", 6", 8", 12", and 18")

Enclosure: ................................................

A:

ABS, UL94-V0, IP65 (NEMA 4X)

C:

Same as A, with terminal block

E:

Same as C, with thread adapter (1/2" NPT to M16),

cable gland fitting, and terminal block

Termination: ..........................................

A:

pigtail, 2 or 3 wire

C & E:

Terminal block, 2 or 3 wire

Country of Origin: ...............................Canada

PRINTED IN C

ANAD

A

TYPICAL WIRE RESISTANCE VALUES

When using low resistance sensors, long wire runs can add

significant error to the readings. Use the following chart to

determine errors due to wire resistance or consider using a

1000 ohm sensor or a transmitter for better accuracy. Locate

the type of wire being used. Multiply the total length of the

wire (distance from the controller to the sensor and back)

by the number found in the chart below for total resistance.

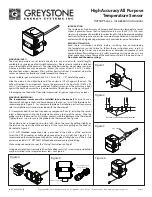

Figure 7 2 Wire Termination for Thermistor

Figure 8 3 Wire Termination for RTD

To Controller

Analog Input (AI)

(No Polarity)

To Controller

Analog Input (AI)

(No Polarity)

To Controller

Analog Input (AI) or

Customer supplied

transmitter

To Controller

Analog Input (AI) or

Customer supplied

transmitter

Green

Black

Red

EMT Connector

EMT Connector

Wiring for Enclosures C & E

GAUGE WIRE TYPE 18 AWG 22 AWG 24 AWG

STRANDED (OHMS/FOOT) 5.85 mΩ 14.75 mΩ 23.29 mΩ

SOLID (OHMS/FOOT) 6.4 mΩ 15.85 mΩ 25.72 mΩ

To Controller

Analog Input (AI)

(No Polarity)

To Controller

Analog Input (AI)

(No Polarity)

To Controller

Analog Input (AI) or

Customer supplied

transmitter

To Controller

Analog Input (AI) or

Customer supplied

transmitter

Green

Red

Black

DIMENSIONS

EMT Connector

EMT Connector

82.5 mm

3.25"

69.8 mm

2.75"

Various Probe Lengths

See Specifications

6 mm

0.236"

76.2 mm

3.00"

0.5" NPT

Foam Gasket

304 Series S/S Probe

*For illustrative purposes only, terminal block mounted on inside of cover

*

*

52 mm

2.05"

NOTE:

The sensor accuracies listed in the specifications section apply to the

sensing element only prior to product assembly and may not be reflected in

the complete assembly.

Due to the measurement uncertainty, it is possible, that the true resistance

value of the single delivered sensor at 0°C can be out of the defined

tolerance class. Profiling each assembly to take into consideration lead wire

and the attachment method should be completed.

IN-GE-HATSAPXXX-02

Copyright © Greystone Energy Systems, Inc. All Rights Reserved Phone: +1 506 853 3057 Web: www.greystoneenergy.com