Greenlee / A Textron Company

9

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

960 PS Series Hydraulic Power Pumps

Maintenance and Service

Maintenance Schedule

Every time the pump is used:

• Check the oil reservoir level. The oil level should be

approximately 13 mm (1/2") from the top of the reser-

voir. If the oil level is low, refer to “Adding Oil” in this

section of this manual.

• Listen for unusual noises and observe the operation of

the pump for changes in performance. Either situation

may indicate that maintenance or repairs

are necessary.

Periodically:

Examine the hydraulic oil for changes in color or viscosity,

and the presence of dirt or other contamination.

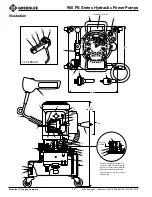

Cleaning

• Periodically clean the exterior of the pump and motor.

Use a vacuum cleaner to clean the ventilation open-

ings.

• Clean the area around the reservoir vent, and be sure

the vent breather hole is open.

• Keep all hose connections clean and use protective

caps or plugs when couplers are not in use.

Inspecting Oil

Inspect the oil occasionally. A change in appearance,

such as darkening or thickening, indicates that the oil

needs to be replaced. Continued use of the oil after it

should be replaced will cause accelerated wear of

system components and will void the warranty.

Adding Oil

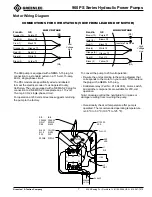

Purging (Bleeding) Air from the System

Erratic performance may be caused by air in the

hydraulic fluid.

Note: Position the pump so that it is above the

accessory. Position the accessory so the hose

connection is upward. This will allow any air in the

accessory to escape into the hose and travel upward to

the pump reservoir.

1.

Remove any items (conduit, cable, etc.) from the

hydraulic accessory.

2.

Rotate the valve clockwise.

3.

Turn the dipstick two turns counterclockwise.

4.

Connect the pump to an appropriate power supply.

5.

Start the hydraulic pump and advance the ram

(hydraulic cylinder) of the accessory to a full stroke

and repeat several times. Stop pump and rotate

valve clockwise to retract ram. As the ram retracts,

the oil in the hose will return to the reservoir in the

pump.

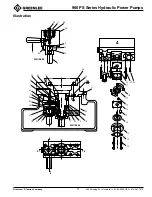

Draining and Flushing the System

1. Thoroughly clean the pump exterior.

2. Remove the motor mounting plate screws.

3. Remove the pump system from the reservoir.

Note: Do not damage the motor mounting plate

gasket, intake screen, or relief valve when removing

the pump.

4. Clean the interior of the reservoir and fill with clean

kerosene. Do not use solvents.

5. Rinse the intake screen.

6. Place the pump system into the reservoir and

replace the motor mounting plate screws.

7. Connect a hose to the pump. Insert the other end of

the hose into the pump reservoir at the fill hole.

8. Run the pump for a few minutes. While the pump

is running, rotate the control lever several times.

Start and stop the pump several times to cycle the

unloading valve.

Note: Do not operate pump for more than a few

minutes as system is not designed to operate with

kerosene.

9. Remove the hose and pump assembly from the

reservoir. Drain and clean the reservoir interior.

Allow the reservoir to dry.

10. Reassemble the pump system.

11. Fill the reservoir. Refer to “Adding Oil” in this section

of the manual.

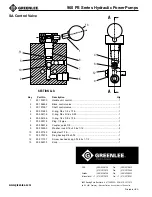

Motor Maintenance

When repairs are necessary, send the motor to one of

the motor manufacturer’s authorized service stations.

Refer to the “Specifications” section of this manual to

determine the correct type of hydraulic oil and Greenlee

part number.

1.

Rotate the valve lever in the clockwise position.

2.

Disconnect the pump from the power supply.

3.

Clean the area around the fill hole.

4.

Remove the reservoir pipe plug.

5.

Use Greenlee hydraulic fluid or an equivalent high

grade light hydraulic oil. Refer to “Specifications” in

this manual.

6.

Pour the oil through a clean funnel with a filter

screen.

7.

Add oil until the oil level is within 13 mm (1/2") from

the reservoir cover.

8.

Replace the pipe plug.

Do not use brake fluid. Brake fluid will ruin the seals.