Greenlee Textron Inc. / Subsidiary of Textron Inc.

4

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

755 Hydraulic Hand Pump

Operation

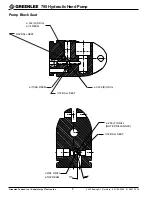

1.

Remove the dust cap.

2.

Connect the hose to the bender or punch unit.

Note:

Hand-tighten the couplers completely.

Do not use tools.

3.

Twist the release knob (7) clockwise until it stops.

4.

Pump the handle (9) until the bend or punch is

complete.

5.

Twist the release knob (7) counterclockwise to

release the hydraulic pressure.

6.

Disconnect the hose from the bender or punch unit.

Replace all dust caps.

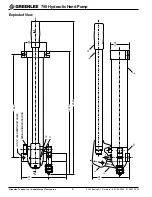

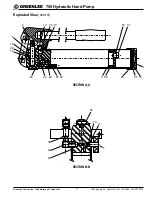

Filling the Pump with Oil

1.

Clamp the pump into a vise with the end cap (1)

upward. Loosen the set screw (26) and remove the

end cap.

2.

Remove the cap screw (31) with O-ring (18) from

the reservoir follower (3). Remove the follower from

the reservoir. Inspect both V-packings (28); replace

them if they are worn or damaged.

3.

Pour Greenlee hydraulic oil* into the reservoir until it

is within 1-3/4" from the top.

4.

Reinstall the reservoir follower.

5.

Turn the release knob (7) counterclockwise so the

valve is open. Pump the handle (9) two or three

times.

6.

Turn the release knob (7) clockwise so the valve is

closed. Pump the handle (9) two or three times.

7.

Slowly turn the release knob (7) to counterclock-

wise. This will allow any air trapped in the pump

block (10) or reservoir (8) to escape.

Note: Do this slowly to prevent the oil from suddenly

gushing up through the cap screw hole.

8.

Repeat steps 5 through 7 one or two more times.

9.

Inspect the O-ring (18) in the cap screw (31);

replace O-ring if it is worn or damaged.

10. Replace the cap screw (31) with O-ring (18) in the

follower (3). Hand-tighten the cap screw.

11. Wipe any excess oil from the outside of the reser-

voir and replace the end cap (1). Tighten the set

screw (26).

*

Order Greenlee hydraulic oil by the gallon

(part number 905 1059.3) or by the quart

(part number 905 0806.8).