XG-Fan Powered Air Terminals Rev 2

3

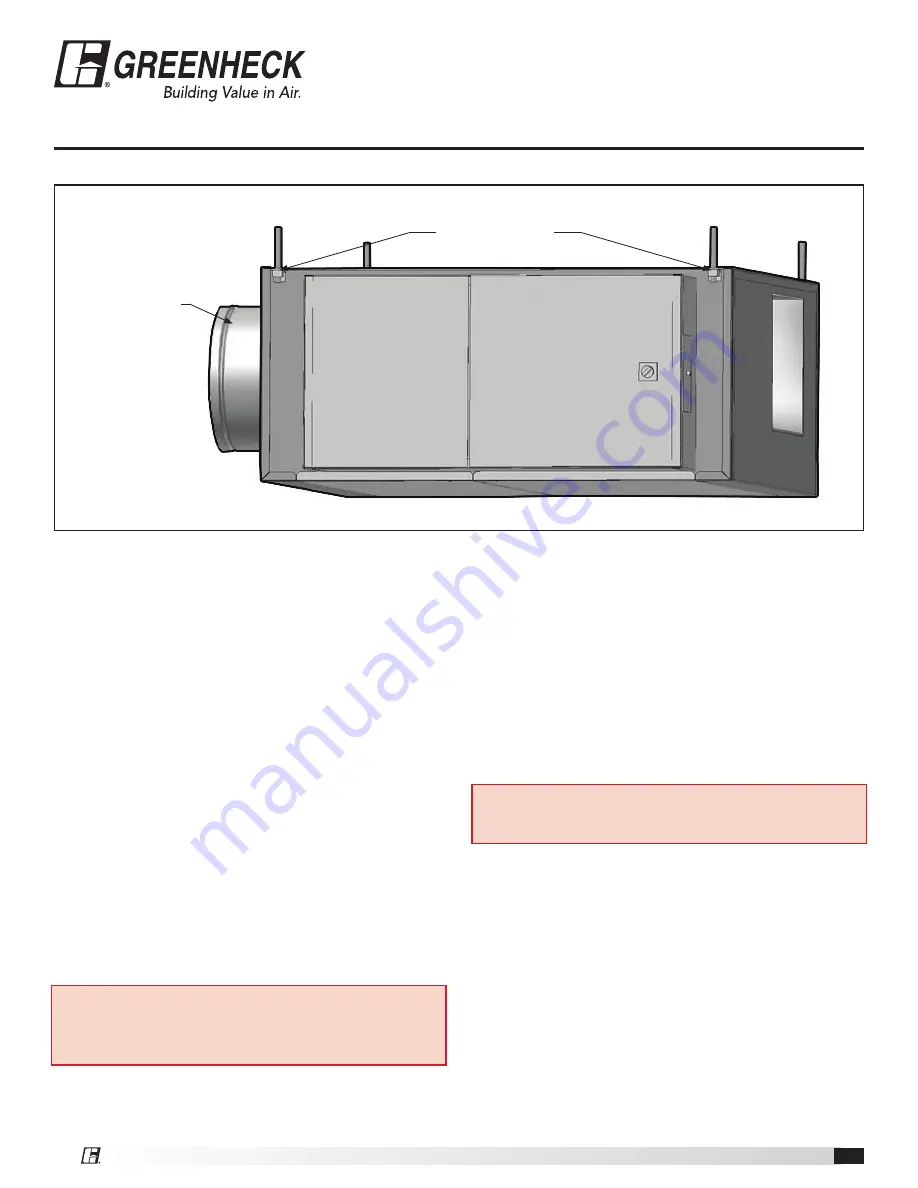

Figure 2 Optional Hanger Brackets and Hanger Rods

Important

If equipped with pneumatic controls, the orientation of the XG-

Fan Powered Air Terminal unit is critical. The pneumatic controls

must be mounted right side up. The XG-Fan Powered Air Ter-

minal must be level or – 10 degrees of horizontal, both

parallel to the air flow and at right angle of air flow. The control

side of the XG-Fan Powered Air Terminal is labeled with an arrow

indicating up. Unless otherwise noted, most electric, analog elec-

tronic and digital are not position sensitive and may be installed in

any orientation.

Minimum Clearance for Access

XG-Fan Powered Air Terminals require sufficient space to allow

servicing of the controls, motor/blower and electric reheat (if

applicable) and single point power hook up. A minimum of 3”of

vertical clearance is required below the bottom of the unit. Hori-

zontal clearance requirements are dependent upon access panel

dimensions which are indicated on the appropriate submittal. For

control panel access, a minimum of 18” is recommended. See the

appropriate submittal for control panel location.

Note

:

These clearances recommendations are not meant

to preclude NEC requirements or local building codes that

may be applicable, which are the responsibility of the installing

contractor.

Connecting Duct Work

1. Slip each inlet duct over the inlet collar of the XG-Fan

Powered Air Terminal.

2. Fasten and seal the connection by method prescribed by

job specification.

3. The diameter of the inlet duct in inches, must be equal

to the listed size of the Fan Powered Air Terminal; e.g. a

duct that actually measures 8 inches must be fitted to a

size 8 inch XG-Fan Powered Air Terminal. The inlet tube

of the XG-Fan Powered Air Terminal is manufactured

1/8” smaller than the listed size in order to fit inside

the duct.

Note

:

Do not insert duct work inside the inlet collar of the

XG-Fan Powered Air Terminal. Inlet duct should be installed

in accordance with SMACNA guidelines.

4. If an inlet air flow sensor is installed, it is recommend-

ed the installer provide a minimum of 3 duct diameters

of straight duct at the XG-Fan Powered Air Terminal

inlet.

5. The outlet end of the XG-Fan Powered Air Terminal is

designed for use with connections flanged outlets.

(Slip and drive duct connections optional.)

6. A rectangular duct the size of the Air Terminal outlet

should be attached.

(Refer to submittal for correct size.)

Hanger brackets and Rod

(5/16” minimum)

Primary air inlet