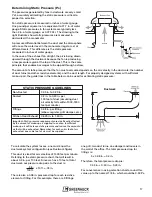

Model

Common Accessories

Roof Curb

G & GB

Backdraft Damper

Roof Curb

CUBE

Grease Trap

SB

Wall Mount Housing or

Wall Mount Collar

Model

Common Accessories

Speed Control

SP & CSP

Discharge Vents

Backdraft Damper

SQ & BSQ

Vibration Isolators

One advantage of choosing the GB-101-4-R2 over the

GB-101-4-R1 is that it is capable of running at higher

rpm’s, which enables the fan to move more air if

necessary.

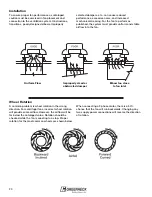

Motor pulleys are adjusted by loosening the set screw

and turning the top half of the pulley (see illustrations at

right). This causes the pulley diameter to change, which

results in changing the fan rpm.

Direct Drive Selection

Selection of direct drive fans (those with the motor shaft

connected to the fan wheel or propeller) is nearly the

same as belt drive selection. However, there are two

differences worth noting. Where belt drive fan speed

can be altered by adjusting the motor pulley, direct

drive fans (since they have no pulleys) must use a

different method.

1. To adjust a direct drive fan's speed (also motor

speed) or to provide a means of meeting an exact

performance requirement, a speed control can be

furnished. Speed controls vary the voltage supplied

to the fan and slows it down; a principle similar to

the way dimmer light switches work.

2. Models CUE and CW, sizes 060-095 and Model SQ,

sizes 60-95, are provided with 115 volt, 60 cycle

motors. The three speeds are 1550 rpm (D), 1300

rpm (G) and 1050 rpm (E). Changing a motor lead is

all that is necessary to change speeds. When

selecting a model with 3 speed motors, it is

recommended that the G speed be chosen whenever

possible. This is the middle speed, which gives the

greatest flexibility in air volume because airflow can

be increased or decreased simply by changing a

motor lead.

Motor Information (Belt Drive Only)

When specifying a belt drive fan, the model designation

does not completely describe the unit. Additional

information about the motor is necessary. These items

are listed below:

Motor Enclosure

This will be either “Open” (open, drip proof), “TE”

(totally enclosed) or “EXP” (explosion resistant). Open

is the most common and will be supplied unless

otherwise specified.

Speeds

Motors are available in either single speed or two

speed. Single speed motors are 1725 rpm. Two speed

motors will be 1725/1140 rpm. Single speed will be

supplied unless otherwise specified.

Electrical Characteristics

Voltage and phase. Voltage can be 115, 208, 230 or

460. Phase is either single or 3 phase. A 115 volt, single

phase motor is shown as 115/1. Typically, motors of

1/2 hp and less are single phase. Motors of 3/4 hp and

greater are 3 phase.

Accessories

Most fans are ordered with accessories. Here are some common accessories for selected models:

6

Opening the pulley decreases fan rpm.

Closing the pulley increases fan rpm.

Belt

Typical Motor Tag

Electrical Instructions

Suffix Letter

Motor Speed

Wiring Connections

D

1550 rpm

White to L1 Black to L2

G

1300 rpm

White to L1 Blue to L2

E

1050 rpm

White to L1 Red to L2