GB-200-5

(512-770)

GB-180-7

(764-1055)

GB-180-5

(700-940)

0.000

0.125

0.250

0.375

0.500

0.625

0.750

0.875

1.000

Sone Bhp Sone Bhp Sone Bhp Sone

Bhp Sone

Bhp Sone

Bhp Sone

Bhp Sone

Bhp Sone

Bhp

STATIC PRESSURE / CAPACITY

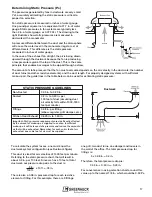

Preliminary Selections

At this point we know the model, cfm and Ps. With this

information we can refer to the GB performance charts

to determine the sizes available to move 2400 cfm

against 0.50 in. Ps.

In our case, all of the criteria can be met by more than

one size of a particular model. When this occurs,

choose the size that provides the greatest airflow range

about the desired cfm. For example, many direct drive

fans have three speeds. If possible, choose a size that

uses the middle rpm. This will allow some final system

adjustment if the actual cfm the job requires is

somewhat higher or lower once the fan is installed. Belt

driven fans have adjustable motor pulleys which allow

the fan speed to be varied. With belt drive units, avoid

selecting near the maximum rpm of a size to allow for

final adjustments if necessary.

There are four GB sizes to choose from in the QD

catalog. These sizes along with their performance data

are in the table below.

Stability Considerations

Whenever there is more than one size to choose from,

it is not recommended to select from the performance

box in the far right column for any given rpm unless the

Ps is known to be accurate. For example, the GB-200

selection (see table below) of 2493 cfm at 0.50 in. Ps is

the far right selection at 700 rpm.

The next box to the right (0.625 in. Ps) is empty

because the performance at that point is unstable. This

means that 2494 cfm at 0.50 in. is marginally stable.

For more information on fan stability, contact

Greenheck.

2522

2433

2346

2258

2166

2062

1942

1792

1602

14.6

0.48

14.3

0.50

13.9

0.51

13.5

0.52

13.1

0.52

12.7

0.52

12.2

0.53

11.6

0.52

11.0

0.51

2866

2787

2709

2634

2556

2475

2384

2286

2176

17.6

0.71

18.0

0.72

17.4

0.74

17.1

0.75

16.8

0.76

15.9

0.77

14.9

0.77

14.8

0.77

14.7

0.78

2318

2104

1875

1587

8.9

0.18

8.5

0.19

8.3

0.19

7.8

0.19

2555

2359

2162

1932

1624

10.6

0.24

10.1

0.25

9.7

0.26

9.4

0.26

8.8

0.25

2909

2737

2567

2382

2176

1914

1550

13.4

0.35

12.7

0.36

12.3

0.37

11.9

0.38

11.5

0.38

10.9

0.37

10.2

0.35

3249

3094

2943

2786

2614

2428

2197

1899

15.3

0.48

14.7

0.50

14.1

0.52

13.8

0.53

13.5

0.53

13.0

0.53

12.5

0.52

12.0

0.50

2994

2833

2651

2427

2139

1700

8.1

0.25

9.2

0.26

9.1

0.29

8.5

0.30

7.8

0.30

7.4

0.28

3150

2997

2832

2624

2375

2053

10.6

0.29

10.3

0.31

10.0

0.33

9.3

0.35

8.6

0.35

8.2

0.34

3500

3364

3219

3052

2858

2624

2347

1821

12.7

0.40

12.4

0.42

12.1

0.44

11.3

0.46

10.5

0.48

10.2

0.48

9.8

0.47

9.2

0.43

3655

3527

3388

3234

3052

2844

2601

2272

13.6

0.46

13.4

0.47

13.1

0.49

12.3

0.52

11.4

0.54

11.0

0.55

10.6

0.54

10.1

0.52

3888

3768

3638

3504

3339

3164

2952

2712

2387

15.2

0.55

14.7

0.57

13.7

0.58

13.3

0.62

13.0

0.64

12.4

0.66

11.9

0.66

11.6

0.65

11.1

0.63

4102

3989

3866

3741

3596

3432

3251

3050

2811

16.2

0.65

15.7

0.67

14.9

0.68

14.4

0.72

14.0

0.74

13.5

0.76

12.9

0.77

12.7

0.77

12.4

0.77

4607

4507

4400

4290

4179

4045

3900

3753

3575

19.0

0.91

18.4

0.94

17.8

0.96

17.4

0.98

17.1

1.03

16.7

1.05

16.2

1.07

15.8

1.10

15.4

1.10

5191

5102

5010

4912

4814

4715

4599

4474

4343

22.0

1.31

22.0

1.33

21.0

1.36

21.0

1.37

21.0

1.41

20.0

1.47

19.9

1.49

19.5

1.51

19.2

1.54

5677

5595

5514

5424

5335

5245

5155

5049

4938

26.0

1.71

25.0

1.74

24.0

1.77

24.0

1.79

24.0

1.81

24.0

1.86

23.0

1.93

23.0

1.95

23.0

1.97

3873

3591

3307

2973

2493

10.3

0.39

9.6

0.40

9.2

0.41

8.6

0.41

7.8

0.40

4260

4013

3744

3477

3140

2643

12.1

0.52

11.0

0.53

10.7

0.55

10.2

0.55

9.8

0.55

9.3

0.52

MODEL

(rpm RANGE)

RPM

Tip

Speed

1360

5207

1545

5915

785

3416

865

3764

985

4287

1100

4787

770

3729

810

3923

900

4359

940

4553

1000

4843

1055

5109

1185

5739

1335

6465

1460

7071

700

3917

770

4308

hp

GB-141

GB-141-5

(1125-1360)

GB-161-4

(634-865)

GB-161-5

(852-1100)

1/2

3/4

1/4

1/2

GB-180-3

(618-810)

GB-180

1/3

1/2

3/4

2

1/2

1

1

/

2

1

Model and Performance Box Data

CFM

Sones

Bhp

RPM

Size

GB-141

2556

16.8

.76

1545

GB-161

2614

13.5

.53

1100

GB-180

2375

8.6

.35

810

GB-200

2493

7.8

.40

700

18