Motor Horsepower

The motor horsepower for direct drive fans is always

sized by Greenheck and does not require further

consideration. For belt drive models, the catalog

identifies which horsepower is recommended.

However, there are times when it is wise to bump the

horsepower one size. For example, the hp

recommended for the GB-180 at 810 rpm is 1/3 hp.

Although a 1/3 hp motor is recommended, it is not

necessarily a good motor selection for this application.

Our static pressure of 0.5 in. was only an estimate. It

may actually turn out to be .625 in.

If this is the case, we will need a 1/2 hp motor because

our fan will have to run at almost 900 rpm (refer to

performance box - 2624 cfm at 0.625 in.Ps). Therefore,

choosing a 1/2 hp motor in this case is exercising good

judgement.

The complete model designation for this application is

GB-180-5.

Note: The GB-180-5 has an rpm range of 700-940

(refer to model column in catalog). This means

that if the static pressure is less than estimated,

say 0.25 in. Ps, the fan can be slowed down to

accommodate this condition.

Sound Levels

In many cases, the sound generated by a fan must be

considered. For the fan industry, a common unit for

expressing sound pressure level is the sone. In

practical terms, the loudness of one sone is equivalent

to the sound of a quiet refrigerator heard from five feet

away in an acoustically average room.

Sones are a linear measurement of sound pressure

levels. For example, a sound level of 10 sones is twice

as loud as 5 sones.

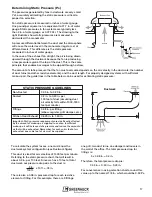

Refer to the Suggested Limits for Room Loudness chart

to determine the acceptable sone range for the

application. As a general guideline, choose a fan that

has a sone value within the range specified.

Note: Rooms with a hard construction (concrete block,

tile floors, etc.) reflect sound. For these rooms, select

fans on the lower end of the range. Rooms with soft

construction or those with carpeting and drapes, etc.,

absorb sound. For these rooms, fans near the higher

end of the range may be selected.

Our example describes an exhaust fan for an office.

Referring to the “Suggested limits for Room Loudness”

chart, offices should have a loudness range from 4 to

12 sones. Of our remaining three selections, only the

GB-180 has a sone value of less than 12. Therefore, the

GB-180 is the best selection for this application.

Suggested Limits for Room Loudness

Sones DBA

1.3-4

32-48

Private homes (rural and suburban)

1.7-5

36-51

Conference rooms

2-6

38-54

Hotel rooms, libraries,

movie theatres, executive offices

2.5-8

41-58 Schools and classrooms,

hospital wards, and operating rooms

3-9 44-60

Court rooms, museums,

apartments, private homes urban)

4-12

48-64

Restaurants, lobbies,

general open offices, banks

5-15

51-67

Corridors and halls, cocktail lounges,

washrooms and toilets

7-21

56-72

Hotel kitchens and

laundries, supermarkets

12-36

64-80

Light machinery, assembly lines

15-50

67-84

Machine shops

25-60

74-87

Heavy machinery

From AMCA Publication 302 (Application of Sone Ratings

for Non Ducted Air Moving Devices with Room-Sone-dBA

correlations).

19