❏

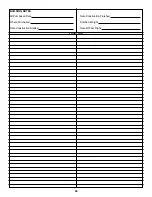

9. Trim the covering from the main landing gear slots on

the bottom of the wing. Apply a small amount of thin CA

along the slot to insure it is fuelproofed.

❏

10. Insert the main landing gear in the landing gear

slots. Position the four

nylon landing gear straps

over the

landing gear and mark the mounting hole locations.

❏

11. Drill a 3/32" [2.4mm] pilot hole at each mark.

❏

12. Attach the landing gear straps to the wing with

#4 x 1/2"

sheet metal screws.

❏

1. Position the

engine mount template

(found on page 21

of this instruction manual) on the firewall. Align the centerlines

of the template with the embossed marks on the firewall.

The marks on the firewall are off center to allow for the

built-in right thrust of the firewall.

❏

2. Mark the engine mount bolt holes and drill a 7/32"

[5.5mm] hole through the firewall at each mark.

❏

3. Insert an

8-32 blind nut

into each hole from the

backside of the firewall. Use an

8-32 x 1" socket head cap

screw

and

#8 flat washer

to seat the blind nuts in the back

of the firewall.

❏

4. Cut the “spreader bar” from the supplied Great Planes

adjustable engine mount.

Use a hobby knife to remove

any flashing left over from the molding process so that the

halves fit together without any binding.

❏

5. Temporarily install the engine mount on the firewall with

four 8-32 x 1" socket head cap screws,

#8 lock washers

and #8 flat washers. Do not tighten the screws all the way

so you can adjust the mount.

❏

6. Place your engine on the mount and adjust the halves

to fit the engine. Position the mount so the molded-in “tick

marks” are equally spaced on the horizontal off set line on

the firewall. When the engine mount is adjusted and

positioned, tighten the mounting screws.

❏

7. Position the engine on the mount so the drive washer

(or the back of the spinner) is 6-1/4" [158.7mm] away from

the firewall.

Use a Great Planes Dead Center

™

Hole

Locator

to mark the engine mounting holes.

❏

8. Drill a 7/64" [2.8mm] hole at each mark. Mount the

engine to the engine mount with four

#6 x 1" sheet metal

screws. Hint:

The screws will be easier to install if you first

rub the threads on a bar of soap.

Note:

On some engines the carburetor can be rotated so

that the needle valve points towards the top of the plane.

ENGINE INSTALLATION

11