D 1 Have someone hold the center of the wing

firmly down to the flat building surface Now grasp

the tip of the wing and twist it so that the trailing

edge raises off the surface While holding in this

twist, use a heat gun to "re-shrink" the covering.

Heat both the top and the bottom When you let go

of the tip, you will see that the wing will retain some

of the twist.

D 2. You must continue twisting and re-shrinking

until the trailing edge is 7/8" off the surface AT

BOTH TIPS As an aid in getting this height correct,

you may make a small wood block 7/8" high by gluing

together pieces of scrap wood Keep this block handy

while twisting and heating, to check your progress.

D 3. Depending on what type of covering you have

used, you may find that, in time, some of the washout

may disappear Check it after an hour and repeat the

above process if necessary Also, re- check it periodi-

cally before you go flying, because THIS IS A VERY

IMPORTANT REASON FOR THE STABILITY OF

YOUR PT40

D FINAL ASSEMBLY

D 1 Lay the rudder and elevator (and ailerons if

you built Wing B) on the plans and mark the hinge

locations on the leading edge of each part Now use

your X-Acto knife (blade must be sharp) to cut slits

in the covering at the hinge locations Trial fit the

hinges to make sure you have "found" the slots which

you previously cut

L] 2. Glue the hinges into the rudder and elevator

(and ailerons) NOTE Do not just smear glue on the

hinge and push it into the slot, as most of the glue

will be wiped off as it is being pushed in You must

also work some glue into the slot A good way of doing

this is to scoop up some epoxy with a plastic soda

straw, then pinch the end of the straw, insert it into

the hinge slot, and squeeze the straw to force glue

into the slot Then insert the hinge hallway into the

slot After pushing in the hinge, wipe away all excess

glue with a tissue.

D 3. After the epoxy has hardened, put glue (15 or

30 minute epoxy is recommended) into the hinge slots

in the stab, and push the elevator hinges into the

slots Wipe away all excess epoxy with a tissue. Re-

peat this process for the rudder

D 4 Wing B only Glue the aileron hinges in place

in the same manner, but also apply epoxy into the

torque rod holes before pushing the ailerons into

place.

D 5. Install 1/4" wide wing seating tape (sticky

side down) onto the wing saddle and the top of the

F-2A (or F-2B) saddles

D 6 Note- Each time you put the wing into the

wing saddle to fly the model, it needs to be in the

same position Follow the steps below so the wing

will be in the correct relationship to the fuselage.

A Place the fuselage on the work surface right

side up Place the wing into the wing saddle Make

the following measurements If the distances you

measure are not the same, move the wing in the wing

saddle until the measurements are the same.

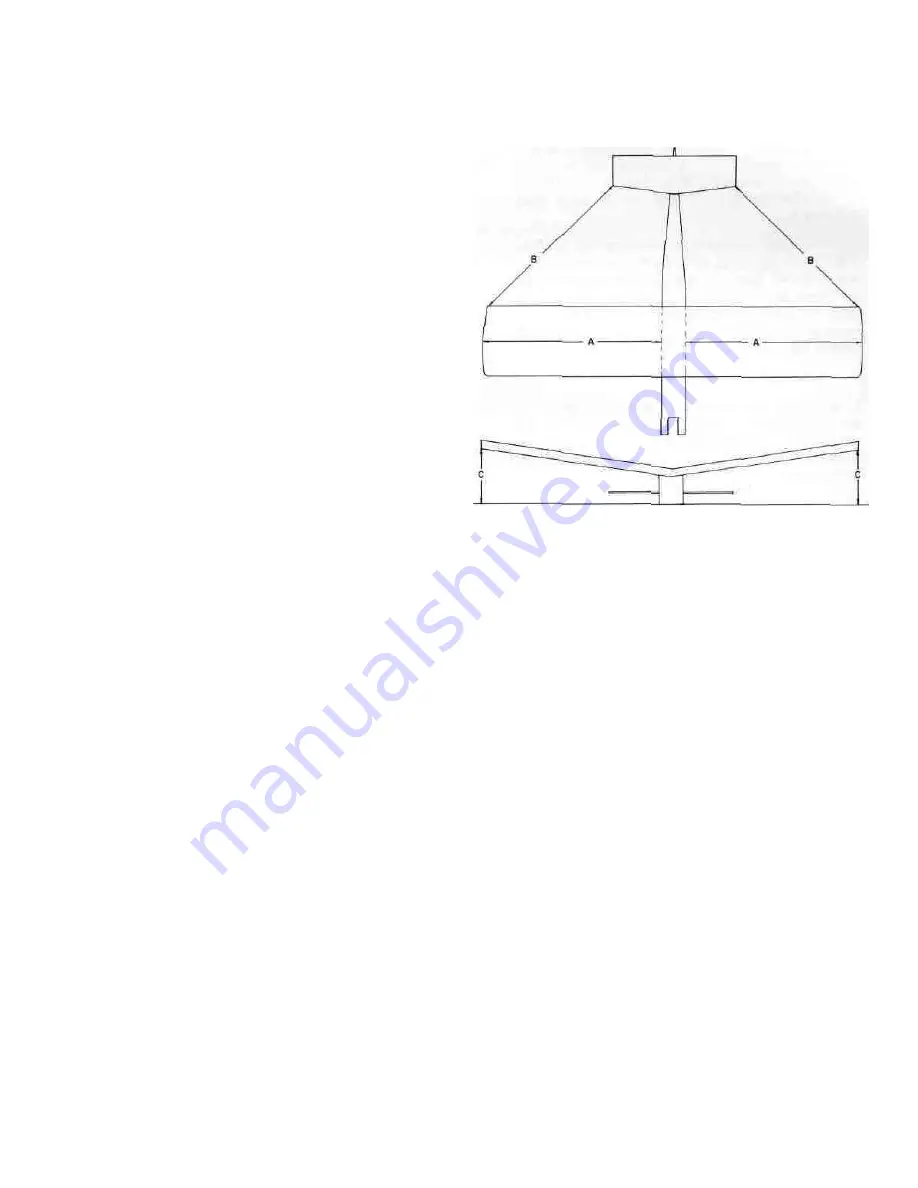

B Measure the wing from side to side in the

saddle The distance from the fuselage side to the

wing tip on each side should be the same. A = A

C Measure from each wing tip to each stab tip.

These distances should be the same. B = B

D Wing tip to work surface distance is the same

on both sides C = C

E When the wing is all lined up to the fuselage

after the above measurements are made, mark a

small line on the wing and a small line on the fusel-

age drawn with a pen on the covering, so you can

put the wing in the same position each time before

you rubber band it.

D 7. Re-install the nose gear assembly, main land-

ing gear, engine and muffler.

D 8 Re- install the nylon horns on the elevator

and rudder For the rudder, you will have to re-drill

the two holes for the 2-56 screws because the lower

hinge now blocks the holes.

D 9 WING B ONLY- Using a sharp X-Acto knife

or single edge razor blade, carefully cut away the

covering from the bottom of the wing where the aile-

ron servo mount will be attached You should be able

to faintly see the dark outline that you previously

drew under the covering Now glue the aileron servo

mount to the bottom of the wing.

D 10. Using an X-Acto knife, cut away the covering

from the rudder, elevator and nose gear pushrod slots;

then re-install the pushrods for the rudder, elevator,

throttle, nose gear and (ailerons).

32