Spartan

II

607

Troubleshooting

Great Plains | 166-486M | 2019/01/29

95

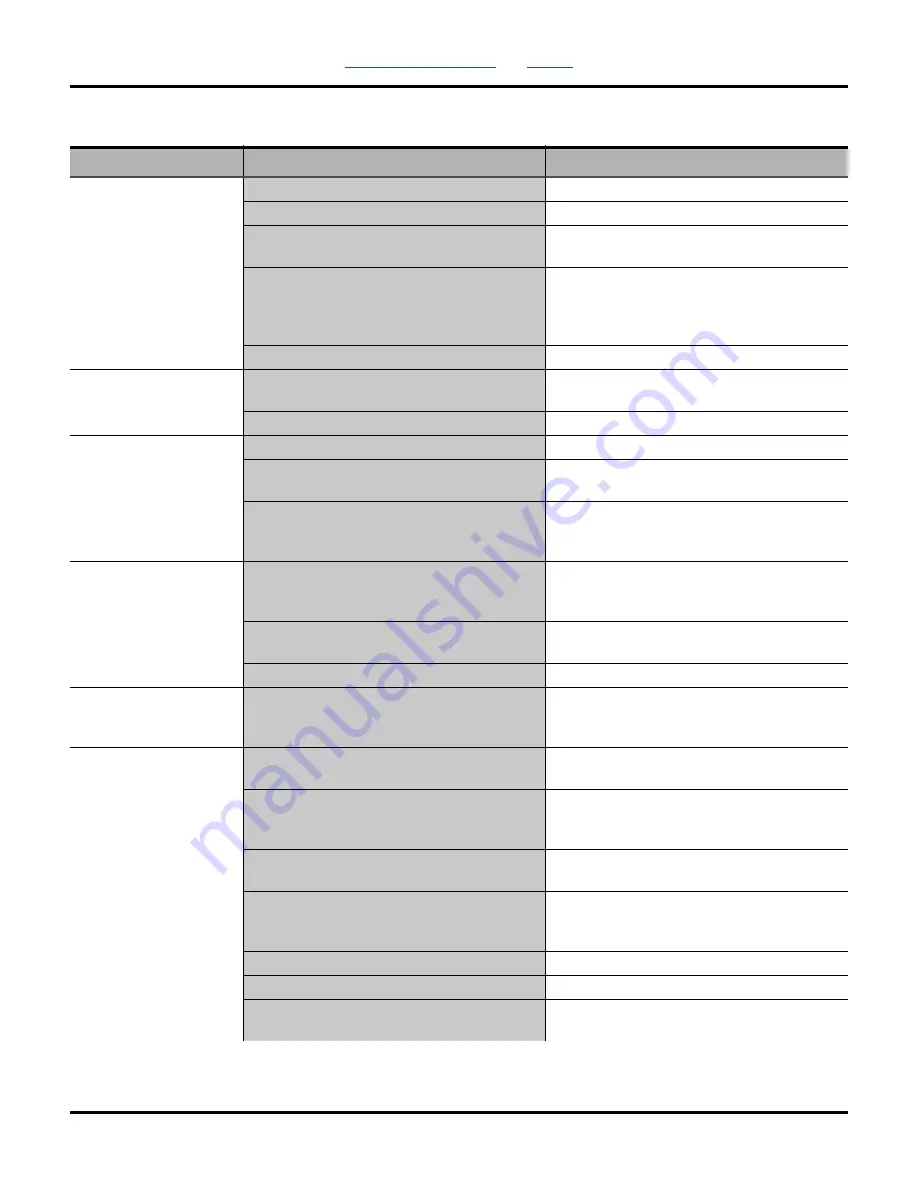

Troubleshooting

Problem

Causes

Solutions

No material flow - all

rows

Empty hopper

Load material.

Meter in use clogged

Clean-out meter (page 73).

Fan not operating

Check hydraulic and electrical connections

for fan.

Fan speed too low

Check pulses-per-rev setting for fan in

terminal. Increase fan speed to

recommended range. See operator manual

for terminal.

Fan running backward

Reverse fan circuit hoses at hitch.

No material flow -

multiple rows

Primary seed hose blocked

Check seed hoses for kinks, congealed

materials at low spots, nests and pests.

Tower inlet or turret blocked

Clear blockage.

No material flow - one

or two rows

Seed tube blocked at row

Inspect and clear seed tube.

Tower port blocked for affected row

Disassemble distribution ring and clear

blockage.

False alarm - blockage sensor disconnected

or failed

Run terminal self-test. Swap sensor with a

working row to verify failure. Replace

sensor.

Material is flowing, but

is not detected by

terminal

This is normal during the first few meters of

planting, as it takes some time for material

to reach rows.

Lower openers 3m before planting is to

begin. Terminal does not check for blockage

during first 5 seconds.

Lift switch not adjusted correctly, failed, or

not wired correctly.

Check, adjust or replace switch (page 75).

Terminal disconnected at hitch

Connect terminal.

Planting too little -

some rows

Partial blockage in meter chamber, seed

hoses, towers, seed tubes

Treat as blockage. See “

Planting too little - all

rows

Incorrect seed rate, meter flutes, or rate

range setting.

Check seed rate information beginning on

page 37.

Air system leaks retarding material flow

above meters

Check hopper lids, meter seals, manifold

caps and seed hose connections. Adjust

latch and/or replace seals as needed.

Seed size and weight or fertilizer density

and granularity vary.

Calibrate. Adjust rate to compensate.

Seed or fertilizer density and granularity

may vary from season to season, batch to

batch and between different suppliers.

Calibrate again if materials might have

changed since last calibration.

Low material level in hopper

Fill hopper.

Fan speed too low

Increase fan speed (page 52).

Fan will not run fast enough

Tractor must be able to supply 68 litres/min

at 14 bar.