Jaguar II User Manual

Installation and Operation of Sign Cutting Plotter 2-13

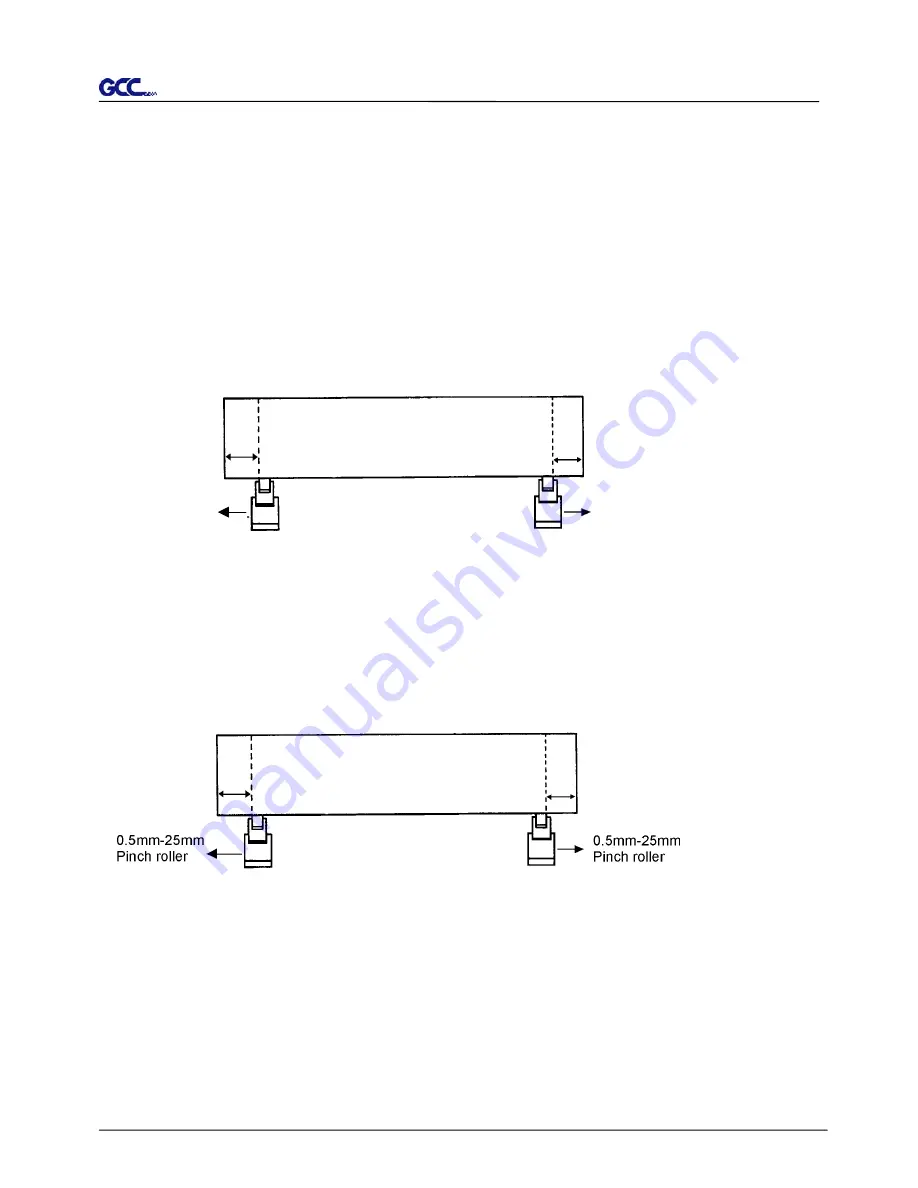

2.6 Tracking Performance

In order to achieve the best tracking performance for a long plot, we recommend some

significant media loading procedures described as follows:

1. If the media length is less than 4 m, leave the margin of 0.5mm

—

25mm in the left and right

edges of the media (see

Figure 2-27

).

2. If the media length is greater than 4m, leave at least 25mm margin on the left and right

edges of the media (see

Figure 2-28

).

Please refer to the paragraph

“Important Information”

at the beginning of the book.

Figure 2-27

Figure 2-28

Pinch roller

Pinch roller

0.5mm - 25mm

0.5mm - 25mm

> or = 25mm

> or = 25mm