GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

No liability for printing errors. Technical modifications reserved!

03/2011

8

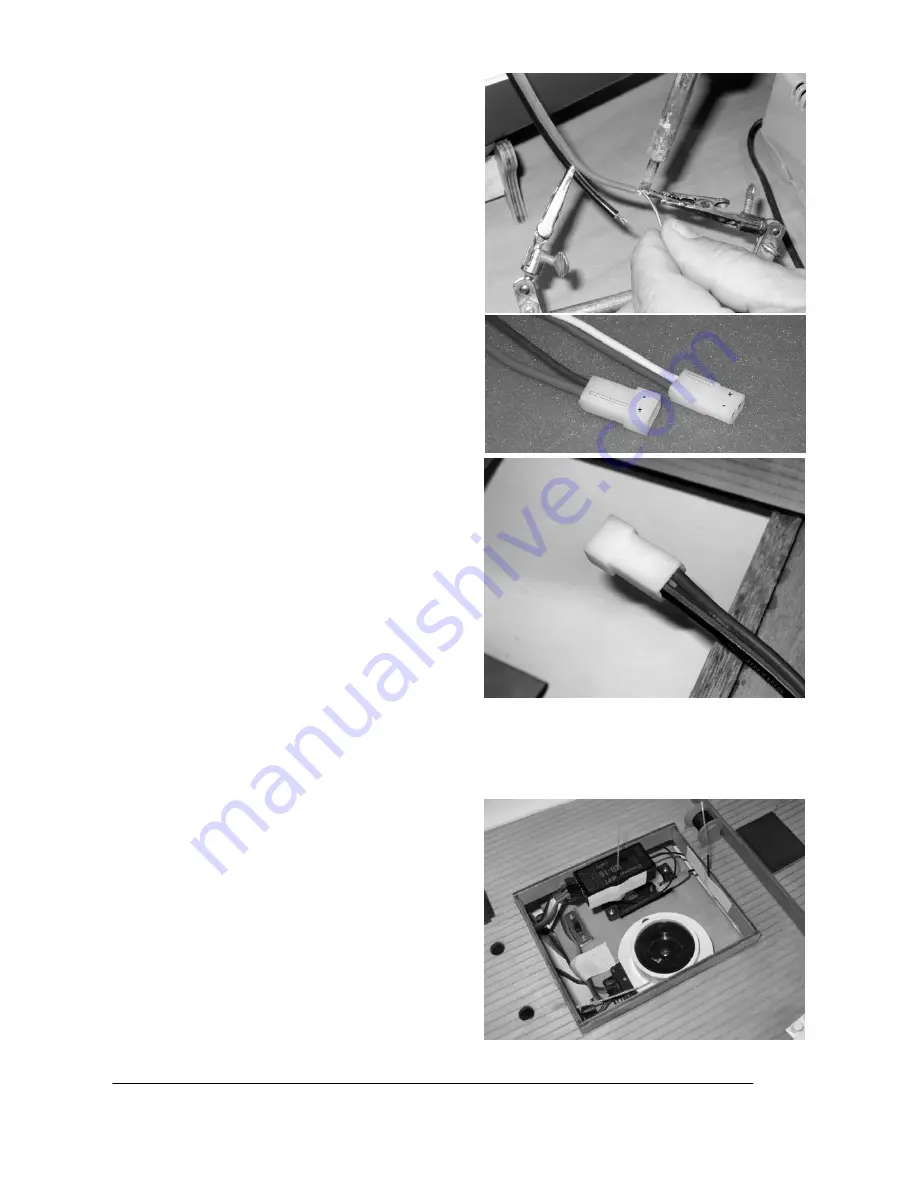

Solder a G2 connector to the motor wires, referring to

the wiring diagram on page 13 (+ is red, - is black).

Check the direction of operation of the motor: when

the battery is connected, the motor shaft must rotate

in such a way that the boat will be propelled forward.

NOTE:

the polarity of the G2 connector system is

designed in such a way that the raised lug on the

plastic housing is always the positive terminal (red

wire). If you keep consistently to this arrangement,

your drive batteries and speed controllers will always

be compatible with each other, and reversed polarity

problems will not arise. We recommend following one

of the tips below in order to make it easier to solder

the joints; this reduces the likelihood of damaging

detail features on the model with the hot soldering

iron.

TIP 1:

remove the motor: undo the grubscrews

in the propeller, then withdraw the propeller. Loosen

the motor retaining screws (accessible through the

two holes in the deck - don’t remove the screws

completely! - and then withdraw the motor to the

point where the shaft coupling is exposed. Loosen

the grubscrews in the coupling which clamp the motor

shaft, and then remove the motor from the model.

Reverse the sequence to re-install it.

TIP 2:

if you

have a friend to help you, ask him or her to hold the

boat at an angle, so that you can hold the wires

outside the hull for soldering the connector.

TIP 3:

it

is possible to solder the joints directly inside the

model (see photo) if you have access to the tool

known as a “third hand”.

Check that the screws in the shaft coupling, the

motor retaining bar and the propeller are tight, as

they may have worked loose in transit. You can

check this by pulling on the propeller: if there is axial

play in the shaft, then one of the grubscrews is loose.

Tighten any loose grubscrews cautiously, following

TIP 1

above to gain access to them.

IMPORTANT:

we recommend that you apply a drop of thread-lock

fluid, e.g. UHU schraubensicher (Order No. 952) to each grubscrew, as vibration when the boat is

operating may cause them to work loose again.

Connect the speed controller wires to those attached to the motor, and fix the controller to the inside of the

hull using Velcro (hook-and-loop) tape.

Connect the two battery connectors to the distributor lead (Order No. 3068).

Attach the receiver to the inside of the coaming under

the bridge superstructure. Stick the aerials of the

HoTT receiver in place, with the final 30 mm of the

aerial wires pointing upward; this will ensure optimum

reception. If you are using a conventional 40 MHz

receiver, the wire aerial must be deployed under the

deck, and taped in place.

IMPORTANT:

it is essential

to locate the aerial or aerials above the waterline,

otherwise radio reception will not be possible.