Maintenance

18

311164M

Maintenance

Preventive Maintenance

Schedule

The operating conditions of your particular system

determine how often maintenance is required. Establish

a preventive maintenance schedule by recording when

and what kind of maintenance is needed, and then

determine a regular schedule for checking your system.

Daily Maintenance

1.

Flush. See

2.

Relieve pressure. See

,

page 13.

3.

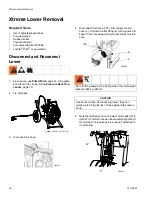

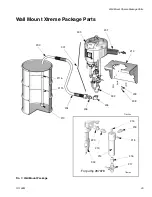

Check packing nut (S, F

. 1). Adjust packings and

replace TSL as necessary. Torque to 25-30 ft-lb

(34-41 N•m).

4.

Drain water from air filter.

5.

Clean suction tube using a compatible solvent. It is

recommended that you clean the outside of the

sprayer using a cloth and compatible solvent.

6.

Check hoses, tubes, and couplings. Tighten all fluid

connections before each use.

7.

Clean fluid line filter.

Corrosion Protection

Always flush the pump before the fluid dries on the dis-

placement rod. Never leave water or water-based fluid in

the pump overnight. First, flush with water or a compati-

ble solvent, then with mineral spirits solvent (also called

white spirit). Relieve the pressure, but leave the mineral

spirits solvent (also called white spirit) in the pump to

protect the parts from corrosion.

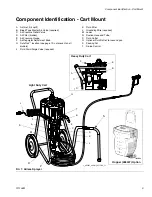

Cart Maintenance

Periodically lubricate the axle between points A and B

with lightweight oil. See F

IG

. 4.

Keep the cart clean by wiping up spills daily, using a

compatible solvent.

NOTE: For overnight shutdown, stop pump at

bottom of its stroke to prevent fluid from drying

on exposed displacement rod and damaging

throat packings. Follow Pressure Relief Proce-

dure, page 13.

F

IG

. 4: Cart Assembly - Heavy Duty Model Shown

r_x25dh1_x45dh1_311164_38f

A

B

Summary of Contents for xtreme

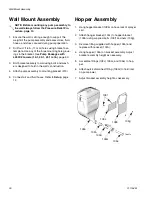

Page 27: ...Hopper Assembly 311164M 27 ...