Prime Empty System

3A0420V

25

Prime Empty System

Prime A and B Fluids

NOTE: The equipment is tested with mineral oil at

the factory. If necessary, flush out the oil with a

compatible solvent before spraying. See

Flush Entire System (new system or end of job),

page 31.

Do not install the gun spray tip yet. To avoid splash-

ing, use the lowest pressure possible to prime.

1. Condition the materials prior to adding to the hop-

pers (J). Ensure that the resin materials are thor-

oughly mixed, homogenous, and pourable prior to

adding to the hopper. Stir the hardeners back into

suspension prior to adding material to hopper.

2. Fill the A and B reservoirs with proper materials. Fill

the A side (blue) with major volume of material; fill

the B side (green) with minor volume of material

(unless 1:1 mix ratio).

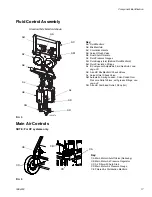

3. Move the recirculation lines (U) to empty containers.

4. Close the dual shutoff handle (AE) and open the cir-

culation handle (AC).

5.

XP Systems only:

Open the main air shutoff valve

(CA). Then slowly open the air regulator (CB).

6.

XP-h Systems only:

Set pump valve on. Then turn

down the pressure control knob.

7. Dispense fluid into the containers until clean fluid

comes out of the A and B recirculation lines.

8. Decrease air pressure. Close the main air shutoff

valve (CA).

9. Move the recirculation lines (U) back to the correct

hopper (J).

10. If using heaters, heat fluid throughout system before

spraying. See

Recirculate Prior to Spraying or

Re-Prime After a Pump Runs Dry

Wear gloves when using flush solvents and/or if the

fluid temperature exceeds 110°F (43°C).

J

U

AC

AE

r_571101_3A0420A_9a-2

CA

CB

ti7108a

ti7111b

Summary of Contents for XP-h

Page 45: ...Repair 3A0420V 45 ...

Page 69: ...Dimensions 3A0420V 69 ...