Setup

3A0420V

23

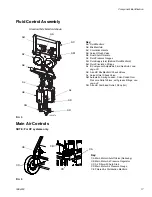

Connect Air Supply

NOTE: For XP systems only.

1. Connect the air supply hose to the 3/4 npt(f) air filter

inlet (C).

NOTE: Use a 3/4 in. (19.1 mm) ID minimum air hose.

Air consumption is 75 cfm per gallon per minute

spraying. Do not use pin fitting type quick discon-

nects.

2. Remove plugs as necessary for solvent pump and

feed supply pump air hoses. See pump manuals for

setup instructions. See F

Connect Hydraulic

Supply/Return Lines

NOTE: For XP-h systems only.

Connect Static Mixers, Gun, and

Hoses

1. Connect the outlet of the two primary static mixer

tubes with mixer elements (W) to the fluid mix

hose (25), cleanup mixer (27, 28), whip hose (30),

and spray gun (31). See F

2. Add mixed material hose as necessary between the

mix hose (25) and cleanup mixer (27, 28).

Connect Fluid Hose Bundles

(Remote Mix Manifold Only)

Connect additional fluid hoses to the fluid manifold (AA)

when the mix manifold (AB) is remote. Hoses must be

properly sized and balanced for your mix ratio. See mix

manifold manual for details.

1. Connect the resin and hardener hoses to the resin

and hardener outlets on the proportioner fluid mani-

fold and resin and hardener inlets on the mix mani-

fold.

F

IG

. 9

F

IG

. 10

C

plug

r_571100_3a0420a_10a-1

WLE

NOTICE

To prevent creating a flare on the mixer tube, do not

use a union swivel end on the mix tube inlet.

F

IG

. 11

AN

25

W

27, 28

30

31

r_5

71100

_3a0

420a

_43a

AB

Standard Mix Manifold shown

Summary of Contents for XP-h

Page 45: ...Repair 3A0420V 45 ...

Page 69: ...Dimensions 3A0420V 69 ...