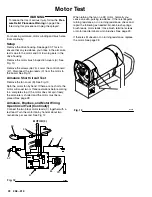

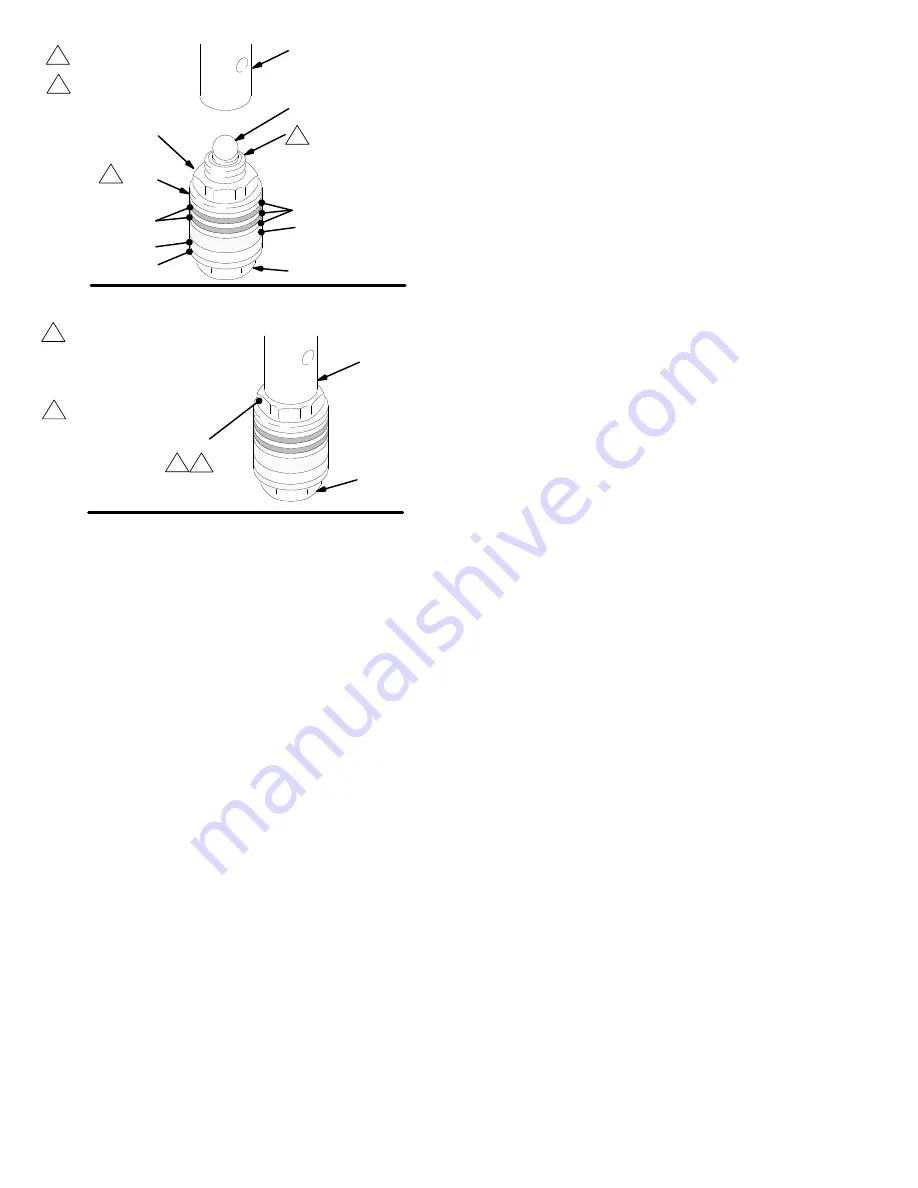

APPLY ONE DROP

OF SEALANT TO

THREADS

109*

*111

*113

112*

107

108

114*

110

Fig. 20

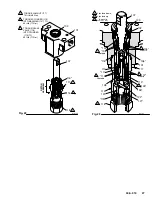

TORQUE TO

2 in-lb (0.23 N.m)

*125

*126

107

110

108

Fig. 21

TORQUE NUT

AGAINST ROD

TO 19 FT–LB

(25 N.m)

DO NOT ALLOW NUT (110)

TO MOVE RELATIVE TO PIS-

TON (108) WHEN TIGHT–

ENING PISTON AGAINST ROD.

7. Place the flats of the rod (107) in a smooth jaw

vise.

8.

CAREFULLY

tighten the nut (110) against the pis-

ton rod to 19 ft-lb (25 N.m). See Fig. 21.

Use two wrenches to maintain the alignment men-

tioned in Fig. 21.

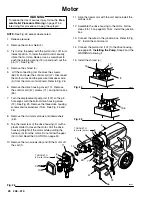

9. Stack these parts one at a time into the top of the

manifold (101): the male gland (106*), alternately

three plastic packings (104*) with two leather pack-

ings (105*), and then the female gland (103*). See

Fig. 23.

10. Install the packing nut (102) and plug (124), but

leave loose for now. See Fig. 23.

11. Place a new o–ring (116*) firmly in the cylinder

groove. See Fig. 22.

12. Coat the piston rod and packings with oil. Carefully

slide the assembly

INTO THE TOP OF THE

CYLINDER (115)

. See Fig. 22.

13. Put the manifold in a vise. Fully thread the jam nut

(117) onto the cylinder (115). Guide the rod/

cylinder assembly down through the manifold

(101). Screw the cylinder (115) into the manifold.

See Fig. 22.

14. Place the ball guide (120), stop pin (122) and ball

(121*) in the cylinder (115). Screw the intake valve

into the cylinder and torque to 53 ft-lb (71 N.m).

This will also properly torque the cylinder into the

manifold. See Fig. 22.

15. Torque the cylinder jam nut (117) to 73 ft–lb (98

N.m). See Fig. 22.

16. Install the pump. See page 24.