308-319

17

Troubleshooting

WARNING

To reduce the risk of serious injury, always follow

the

Pressure Relief Procedure

on page 3 before

checking or repairing any part of the sprayer.

Check everything in the guide before disassembling

the sprayer.

NOTE:

Thaw sprayer if water or water–based paint

has frozen in it, due to exposure to low temperatures,

by placing it in a warm area. Do not try to start sprayer

until it has thawed completely or damage to motor and/

or control board may occur. If paint hardened (dried) in

sprayer, the pump packings and/or pressure transduc-

er must be replaced. See page 24 (pump) or 32 (pres-

sure transducer).

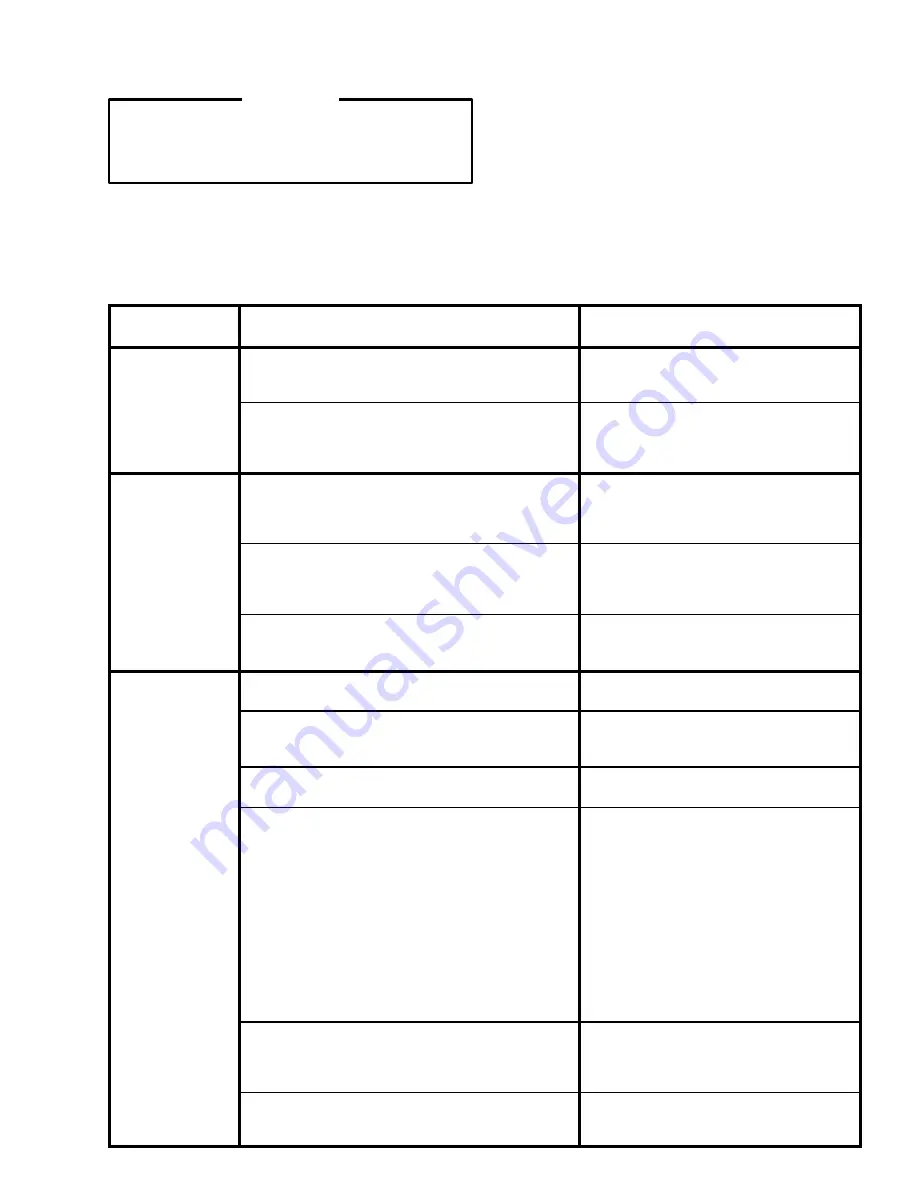

Basic Problem Solving

TYPE OF

PROBLEM

WHAT TO CHECK

If check is OK, go to next check

WHAT TO DO

When check is not OK, refer to this column

Fluid Pressure

1. Check pressure transducer knob setting. The

pump won’t develop much pressure if it is at mini-

mum setting (fully counterclockwise).

1. Slowly increase pressure setting to see if

motor starts.

2. Check for a clogged spray tip or fluid filter, if used.

See page 11.

2. If tip is still clogged, relieve pressure;

refer to separate gun or tip instruction

manual for tip cleaning. Clean or replace

filter element. See manual 308–249.

Mechanical

1. Check for frozen or hardened paint in pump (20).

Using a screwdriver, carefully try to rotate fan at

back of motor by hand. See page 28.

1. Thaw. Plug in sprayer and turn on.

Slowly increase pressure setting to see if

motor starts. If it doesn’t, see NOTE

above.

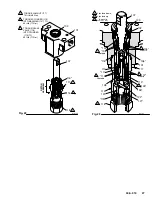

2. Check pump connecting rod pin (17). It must be

completely pushed into connecting rod (15), and

retaining spring (18) must be firmly in connecting

rod groove. See Fig. 18, page 24.

2. Push pin into place and secure with

spring retainer.

3. Check for motor damage. Remove drive housing

assembly (11). See page 30. Try to rotate motor

fan by hand.

3. Replace motor (4) if fan won’t turn. See

page 28.

Electrical

1. Check electrical supply with volt meter. Meter

should read 105–125 VAC.

1. Reset building circuit breaker; replace

building fuse. Try another outlet.

2. Check extension cord for visible damage. Use a

voltmeter or test lamp at extension cord outlet to

check.

2. Replace extension cord.

3. Check sprayer power supply cord (50) for visible

damage such as broken insulation or wires.

3. Replace power supply cord. See page

29.

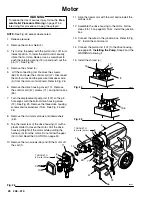

4. Check motor brushes for the following:

a. Loose terminal screws.

b. Broken or misaligned brush springs.

c. Brushes binding in holders.

d. Broken leads.

e. Worn brushes.

f. Brush leads snagged on spring clip.

NOTE:

The brushes do not wear at same

rate on both sides of motor. Check both

brushes.

4. Refer to page 23.

a. Tighten.

b. Replace broken spring and/or align

spring with brush

c. Clean brush holders. Remove carbon

with small cleaning brush. Align brush

leads with slot in brush holder to as-

sure free vertical brush movement.

d. Replace brushes

e. Replace brushes if less than 0.4”

(10 mm) long.

f. Correctly route the wires. See page 23.

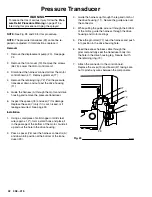

5. Check motor armature commutator for burn spots,

gouges and extreme roughness. Remove motor

cover and brush inspection plates to check. See

page 23.

5. Remove motor and have motor shop

resurface commutator if possible. See

page 28.

6. Check motor armature for shorts using armature

tester (growler) or perform motor test. See page

22.

6. Replace motor. See page 28.