General Repair Information

WARNING

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including

fluid injection, splashing fluid or solvent in the eyes or

on the skin, or injury from moving parts or electric

shock, always follow this procedure whenever you

shut off the sprayer, check or service any part of the

spray system, install, clean or change spray tips, and

whenever you stop spraying.

1. Engage the gun safety latch.

2. Turn the ON/OFF switch to OFF.

3. Unplug the power supply cord.

4. Disengage the gun safety latch. Hold a metal

part of the gun firmly to the side of a grounded

metal pail, and trigger the gun to relieve pres-

sure.

5. Engage the gun safety latch.

6. Open the pressure drain valve, having a con-

tainer ready to catch the drainage. Leave the

valve open until you are ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, VERY SLOWLY

loosen the tip guard retaining nut or hose coupling to

relieve pressure gradually, then loosen completely.

Now clear the tip or hose.

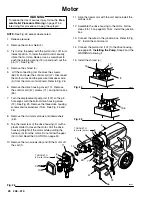

Tool List

These service tools are required.

1/4” Allen wrench:

filter plug

3/8” Allen wrench:

pump manifold

3/16” Allen wrench:

gear housing, legs, handle

5/64” Allen wrench:

pressure adjustment knob

#1 Phillips

screwdriver:

junction box, front cover

,

motor shield

3/8” socket wrench:

motor mount

5/8” socket wrench:

drain valve, outlet fittings,

on/off switch boot, piston

13/16” socket wrench:

drain valve

1-1/4” socket wrench:

pump inlet valve

1/2” open end wrench:

pump rod

11/16” open end wrench:

piston jam nut

15/16” open end wrench:

flats of inlet tube

1-3/4” open end wrench:

pump jam nut

5/64” drive pin:

drain valve pin

3” needle nose pliers:

wiring, on/off switch

Hammer & punch:

packing nut

Torque wrenches:

various fasteners

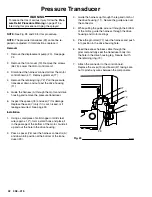

CAUTION

To reduce the risk of a pressure transducer mal-

function, properly mate connectors and never pull

on a wire to disconnect it.

1.

When disconnecting wires

, use needle nose

pliers to separate mating connectors.

2.

When reconnecting wires

, center the flat blade

of the male connector in the blade of the female

connector.

3.

Route wires carefully

and avoid pinching any

wires between covers.

CAUTION

Improper wire routing can result in poor sprayer

performance or damage to the pressure trans-

ducer.

4.

Keep all screws, nuts, washers, gaskets, and

electrical fittings

removed during repair proce-

dures.

5.

Test your repair before regular operation

to be

sure the problem is corrected.

6.

If the sprayer does not operate properly

, verify

that everything was done correctly. Also refer to

the Troubleshooting Guide, page 17, to help iden-

tify other possible problems and solutions.

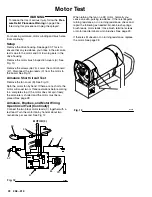

WARNING

To reduce the risk of serious bodily injury, including

electric shock, DO NOT touch any moving parts or

electrical parts with your fingers or a tool while in-

specting the sprayer.

Shut off the sprayer and unplug it as soon as you

complete the inspection.

Reinstall all covers, gaskets, screws and washers

before operating the sprayer.

WARNING

During operation, the motor and drive housing be-

come very hot and could burn your skin if touched.

Flammable materials spilled on the hot, bare motor

could cause a fire or explosion.