8

309977

Troubleshooting

LOW OR FLUCTUATING OUTPUT

TYPE OF PROBLEM

WHAT TO CHECK

If check is OK, go to next check

WHAT TO DO

When check is not OK refer to this column

Low Output

1. For worn spray tip.

1. Follow

Pressure Relief Procedure Warn-

ing,

then replace tip. See your separate

gun or

tip manual.

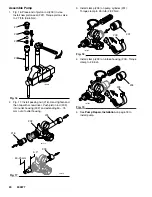

2. Verify pump does not continue to stroke when

gun trigger is released.

2. Service pump. Check piston and intake

valves for wear or obstructions.

See page 18.

3. Filter clogged (If optional filter is installed).

3. Relieve pressure. Check and clean filter.

4. Material hose length. Longer hose length re-

duces sprayer performance.

4. Replace with hose length less than speci-

fied maximum.

5. Pump hopper adapter connections.

5. Tighten any loose connections. Replace

pump hopper adapter if cracked or punc-

tured.

6. Electrical supply with volt meter.

Meter must read:

210–255 Vac for 220–240 Vac models;

85–130 Vac for 100–120 Vac models.

Low voltages reduce sprayer performance.

6. Reset building circuit breaker; replace

building fuse. Repair electrical outlet or try

another outlet.

7. Extension cord size and length; must be at least

1.0 mm

2

(12 awg) wire and no longer than 90 m

(295 ft). Longer cord lengths reduce sprayer

performance.

7. Replace with a correct, grounded exten-

sion cord.

8. Leads from motor to pressure control circuit

board (38) for damaged or loose wires or con-

nectors. Inspect wiring insulation and terminals

for signs of overheating.

8. Be sure male terminal blades are centered

and firmly connected to female terminals.

Replace any loose terminal or damaged

wiring. Securely reconnect terminals.

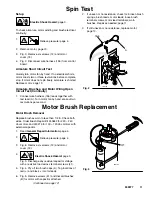

9. For loose motor brush leads and terminals. See

page 11.

9. Tighten terminal screws. Replace brushes

if leads are damaged. See page 11.

10.For worn motor brushes which must be 1/4 in.

minimum. See page 11.

10. Replace brushes. See page 11.

11. For broken and misaligned motor brush

springs. Spring must rest squarely on top of

brush.

11. Replace brush if spring is broken. See

page 11.

12.Motor brushes for binding in brush holders.

See page 11.

12.Clean brush holders, remove carbon dust

with small cleaning brush. Align brush lead

with slot in brush holder to assure free verti-

cal brush movement.

13.Low stall pressure.

13. Do either or both:

a.

Turn pressure control knob fully

clockwise. Make sure pressure

control knob is properly installed to

allow full clockwise position.

b.

Try a new transducer.

14.Motor armature for shorts by using an armature

tester (growler) or perform spin test.

See page 11.

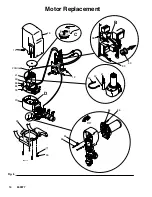

14.Replace motor. See page 13.

Summary of Contents for T-Max 405 248195

Page 30: ...30 309977 Notes ...