11

309977

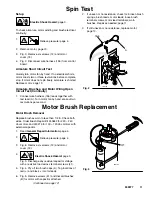

Spin Test

Setup

Electric Shock Hazard;

page 3.

To check armature, motor winding and brush electrical

continuity:

1.

Relieve pressure

;

page 4.

2.

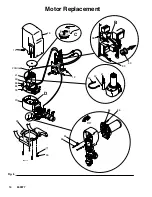

Remove motor, page 13.

3.

Fig. 3. Remove six screws (12) and motor

cover (18).

4.

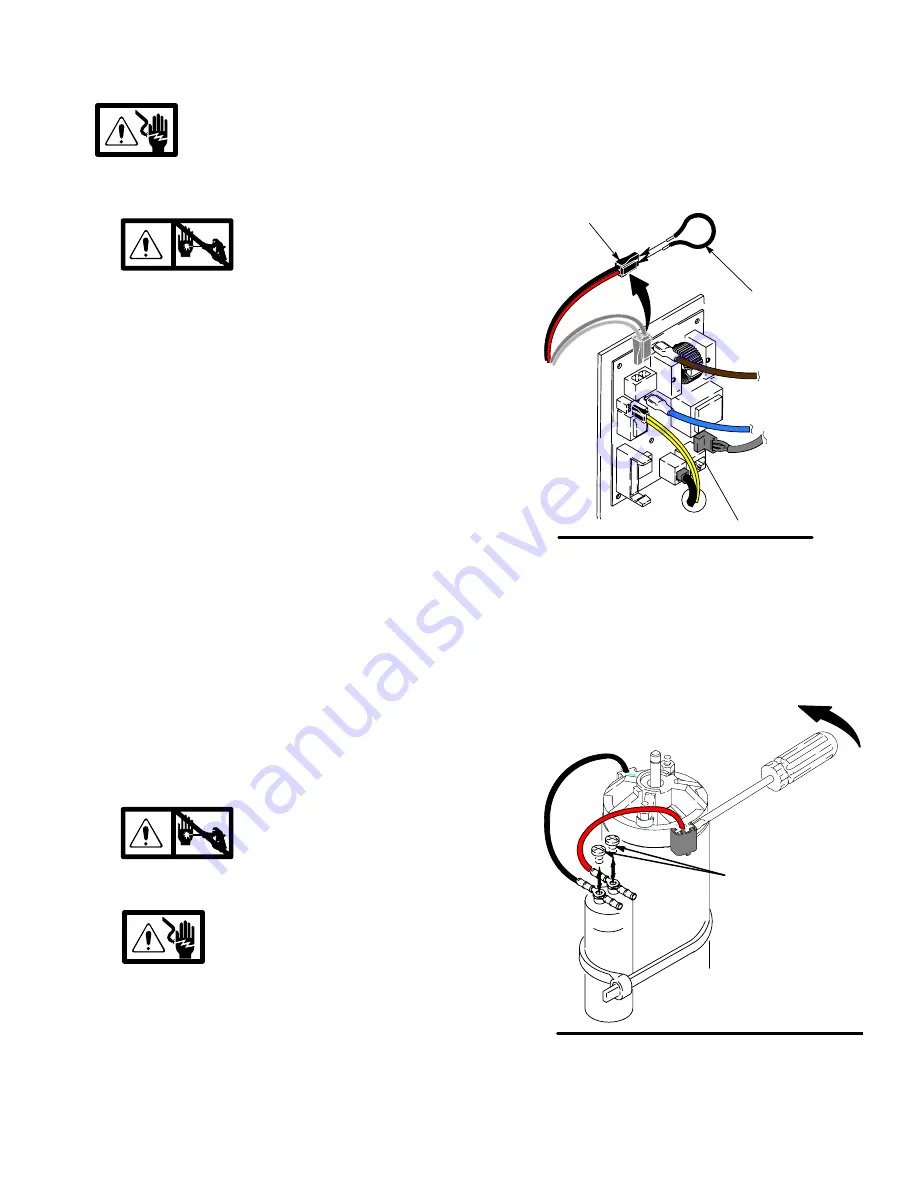

Fig. 2. Disconnect wire harness (155) from control

board.

Armature Short Circuit Test

Quickly turn motor fan by hand. If no electrical shorts,

motor coasts two or three revolutions before complete

stop. If motor does not spin freely, armature is shorted.

Replace motor; page 13.

Armature, Brushes, and Motor Wiring Open

Circuit Test (Continuity)

1.

Connect wire harness (155) leads together with

test lead (A). Turn motor fan by hand at about two

revolutions per second.

2.

If uneven or no resistance, check for: broken brush

springs, brush leads, motor leads; loose brush

terminal screws, motor lead terminals; worn

brushes. Repair as needed; page 11.

3.

If still uneven or no resistance, replace motor;

page 13.

Fig. 2

ti4816a

155

A

Motor Brush Replacement

Motor Brush Removal

Replace brushes worn to less than 1/2 in. Check both

sides. Order Brush Repair Kit 243642 for 220 – 240

Vac motors and 243215 for 100 – 120 Vac motors with

external capacitor.

1.

Read

General Repair Information

; page 4.

2.

Relieve pressure

;

page 4.

3.

Fig. 6. Remove six screws (12) and motor

cover (18).

4.

Electric Shock Hazard;

page 3.

Fig. 3. Discharge any residual capacitor voltage

with a resistive load across terminal screws (41).

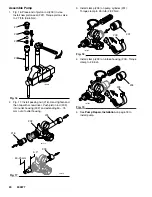

5.

Fig. 4. Pry off two brush caps (A). Tag locations of

red (+) and black (–) motor leads.

6.

Fig. 5. Remove screws (41) and discard brushes

(B) for motor with capacitor attached.

(Continued on page 12)

Fig. 3

41

ti4815a

Summary of Contents for T-Max 405 248195

Page 30: ...30 309977 Notes ...