Operation

309457G

21

Operation

Fluid Voltage Discharge and

Grounding Procedure

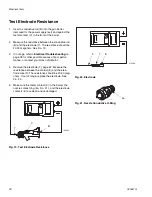

NOTE: An accessory grounding rod, part No. 210084, is

available to discharge any voltage remaining on a sys-

tem component. Contact your Graco distributor to order.

1.

Turn off the turbine air to all spray guns connected

to the isolated fluid supply.

2.

Discharge the voltage at the voltage isolation sys-

tem by following the procedure specified in the volt-

age isolation system instruction manual.

3.

Touch the electrode of the gun with a grounded rod

to make sure the voltage has been discharged. If

you see an arc, verify that the electrostatics are

turned off or see Electrical Troubleshooting on

page 38 or the voltage isolation system manual for

other possible problems. Resolve the problem

before proceeding.

Pressure Relief Procedure

1.

Follow the Fluid Voltage Discharge and Ground-

ing Procedure, on page 21.

2.

Relieve fluid pressure in the fluid supply and voltage

isolation system as instructed in their instruction

manuals.

3.

Turn off all the air to the spray gun except the cylin-

der air, which triggers the gun. If an air pilot fluid

regulator is used in the system, air pressure is also

needed at the regulator air inlet.

NOTE: The air shut-off device must bleed the air out of

the system.

4.

Trigger the gun into a grounded metal waste con-

tainer to relieve the fluid pressure.

5.

Turn off all remaining air supplies to the gun.

6.

Turn off the main air supply by closing the

bleed-type master air valve on the main air supply

line. Leave the valve closed until you are ready to

spray again.

WARNING

Electric Shock Hazard

The high voltage fluid supply is charged

with high voltage until the voltage is dis-

charged. Contact with the charged compo-

nents of the isolation system or spray gun

electrode will cause an electric shock. To avoid an

electric shock, follow the Fluid Voltage Discharge

and Grounding Procedure:

•

when instructed to discharge the voltage

•

before cleaning, flushing, or servicing the system

equipment

•

before approaching the front of the gun

•

or before opening the safety fence or enclosure

for the isolated fluid supply.

WARNING

Pressurized Equipment Hazard

The system pressure must be manually

relieved to prevent the system from starting

or spraying accidentally. To reduce the risk

of an injury from electric shock, accidental spray from

the gun, splashing fluid, or moving parts, follow the

Pressure Relief Procedure whenever you:

•

are instructed to relieve the pressure

•

stop spraying

•

check or service any of the system equipment

•

or install or clean the fluid nozzle.

Summary of Contents for PRO Auto Xs

Page 51: ...Repair 309457G 51 ...