28 308496

Troubleshooting

Voltage Loss Troubleshooting (continued)

11. A dielectric breakdown is most likely in one of the

following three areas. Repair or replace the com-

ponent that is failing.

Fluid hose

Check for leakage or any bulges in the outer

jacket, which may indicate a pin-hole leak

through the PTFE

layer. Disconnect the fluid

hose from the gun, and look for signs of fluid

contamination on the outside of the PTFE

portion of the fluid tube.

Inspect the end of the hose connected to the

voltage block. Look for cuts or nicks.

Make sure the hose is properly stripped; see

Fig. 12, page 15, for hose stripping dimen-

sions. Restrip or replace the hose.

Fluid packings

Remove the packing assembly from the gun

as instructed on page 38, and look for signs of

fluid leakage or any blackened areas, which

would indicate arcing is occurring along the

packing rod.

Fluid hose connection joint to the spray gun

A breakdown at the fluid hose connection joint

would be caused by fluid leaking past the

o-ring seals on the end of the hose. Remove

the hose at the gun connection and look for

signs of fluid leakage along the PTFE tube.

12. Before reassembling the gun, clean and dry the

gun fluid inlet tube (item 17 on page 50). Repack

the inner spacer of the fluid packing rod with

dielectric grease and reassemble the gun.

13. Reconnect the fluid hose as instructed on page 15.

14. Check the gun voltage with the voltage probe and

meter before filling the gun with fluid.

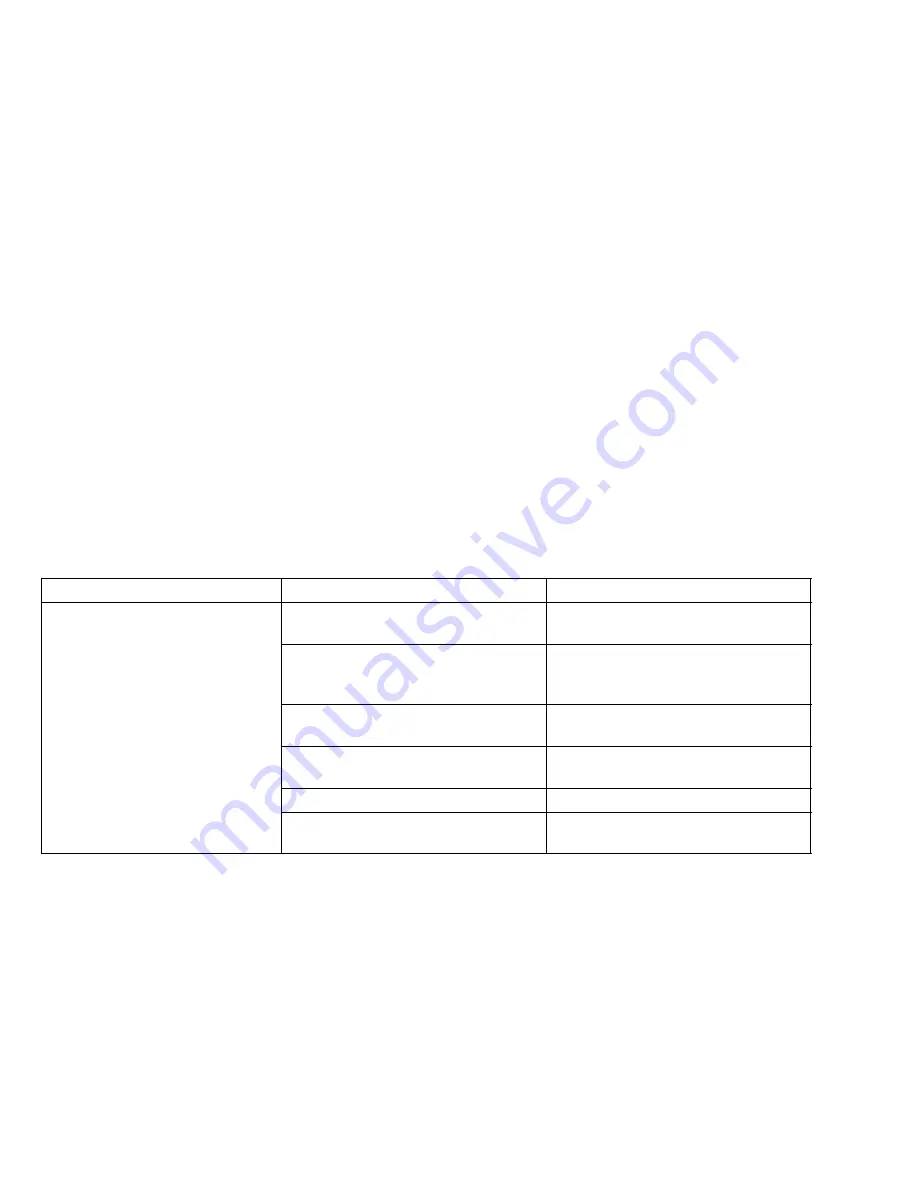

Poor Electrostatic Wrap Troubleshooting

Problem

Cause

Solution

The system is holding voltage but

there is poor electrostatic wrap on

The distance between the gun and

workpiece is incorrect.

Adjust the spraying distance to 8 to

12 inches (203 to 305 mm).

the part being sprayed

The parts are poorly grounded.

Clean the workpiece hangers; check

for proper grounding on the conveyor

or track.

Booth exhaust velocity is too high.

Reduce the exhaust velocity within

the code limits.

The atomizing air pressure is too

high.

Reduce the atomizing air pressure.

The fluid pressure is too high.

Reduce the fluid pressure.

The fluid viscosity is not right for

electrostatic spray.

Check with the supplier for proper

fluid viscosity for electrostatic spray.

Summary of Contents for PRO 5500wb

Page 49: ...308496 49 Notes ...

Page 59: ...308496 59 Notes ...