Installation

10

3A5266G

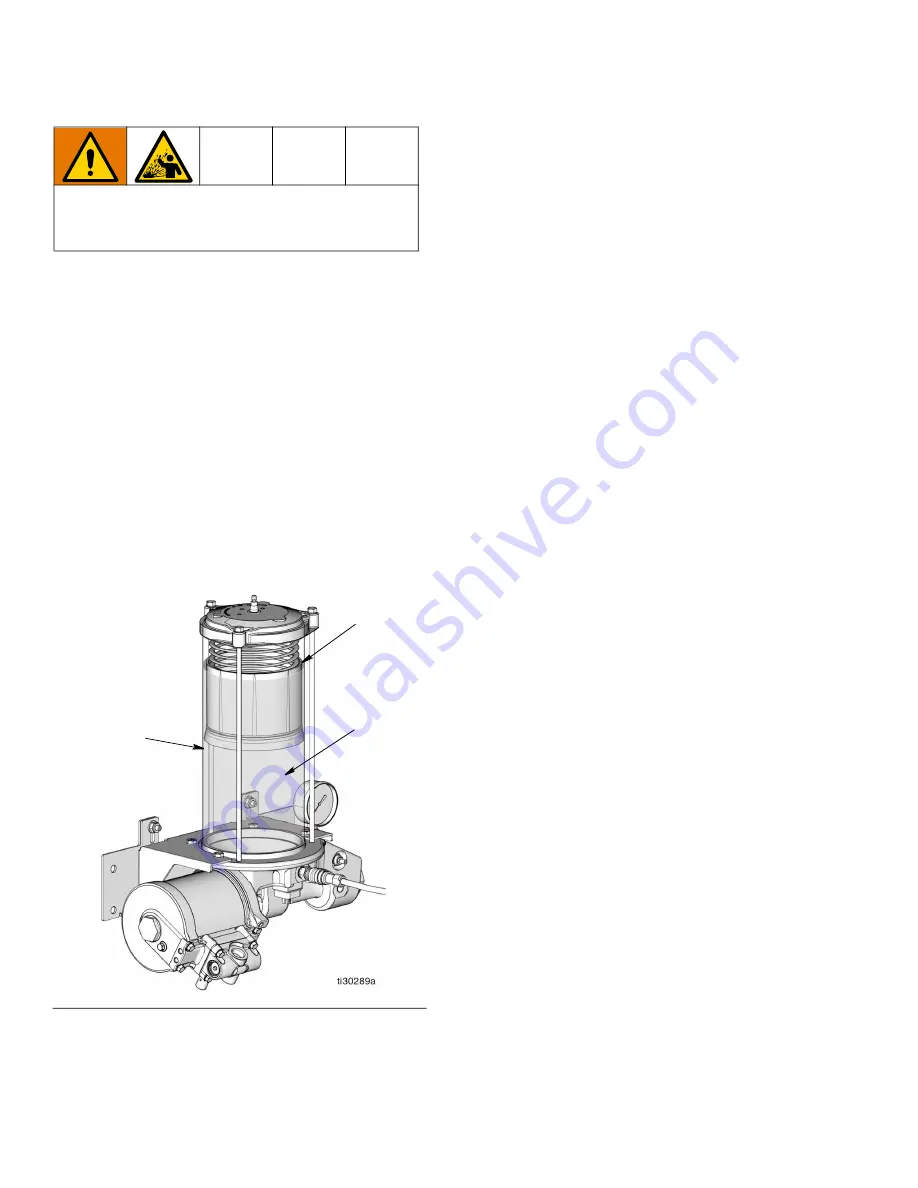

3. Slowly dispense grease from the fill pump into the

reservoir until the grease in the reservoir lifts the fol

-

lower plate (45) above the reservoir vent hole (vh)

and air is expended from under the follower plate

. 9). A small amount of grease may come out of

the vent hole at this time.

Care must be taken not to overfill the reservoir. An

over filled reservoir will vent the excess grease out

of the vent hole (vh) until enough grease is expelled

for the follower plate (45) to block the vent hole.

Overfilling the reservoir could also cause the reser

-

voir to rupture due to over-pressurization.

NOTE:

The vent hole (

vh

)

is located toward the back

right side of the reservoir and cannot be seen in F

. 9.

The approximate location of the vent hole is identified

as

vh

in the illustration.

4. Disconnect the fill pump from the fill stud (26, F

8).

5. Secure dust cap (42) over fill stud (26) (F

. 8).

Priming

Refer to F

. 2, pages 5 and 6, for the follow

-

ing instructions.

NOTE:

• Prime the pump before connecting the outlet to

supply line (G).

• Before priming the pump, the reservoir must be

filled with lubricant (see Fill Reservoir instructions,

page 8).

Run the pump until lubricant, free of air, comes out of

the pump outlet (E). It may take up to 20 pump strokes

to expel the air from the pump and deliver a continuous

flow of lubricant. This will depend on the viscosity of the

lubricant and temperature.

Supply Lines

1. Run the pump until the oil (

ol

), free of air, comes out

of the pump outlet (E). Connect the supply line (G)

to the pump outlet (E).

2. If there are multiple pumps on the air line, close the

air regulators and bleed-type master air valves to all

but one of the pumps. If there is only one pump,

open its air regulator and bleed-type master air

valve.

3. Open the master air valve from the compressor.

4. Set the air pressure to each pump at the lowest

pressure needed to get the desired results.

Feeder Lines

Fill each feeder line with lubricant prior to connecting

feeder lines to the injector outlet or divider valve.

Injectors

1. Check each injector for proper operation. The injec

-

tor stem should move when lubricant is discharged.

2. Adjust the injector output if needed to ensure that

the output volume discharged is sufficient.

Over-pressurization can result in equipment rupture

and serious injury. Fill slowly to avoid over pressuriz

-

ing reservoir.

F

IG

. 9

45

(vh)

(gr)