Troubleshooting

3A0245A

17

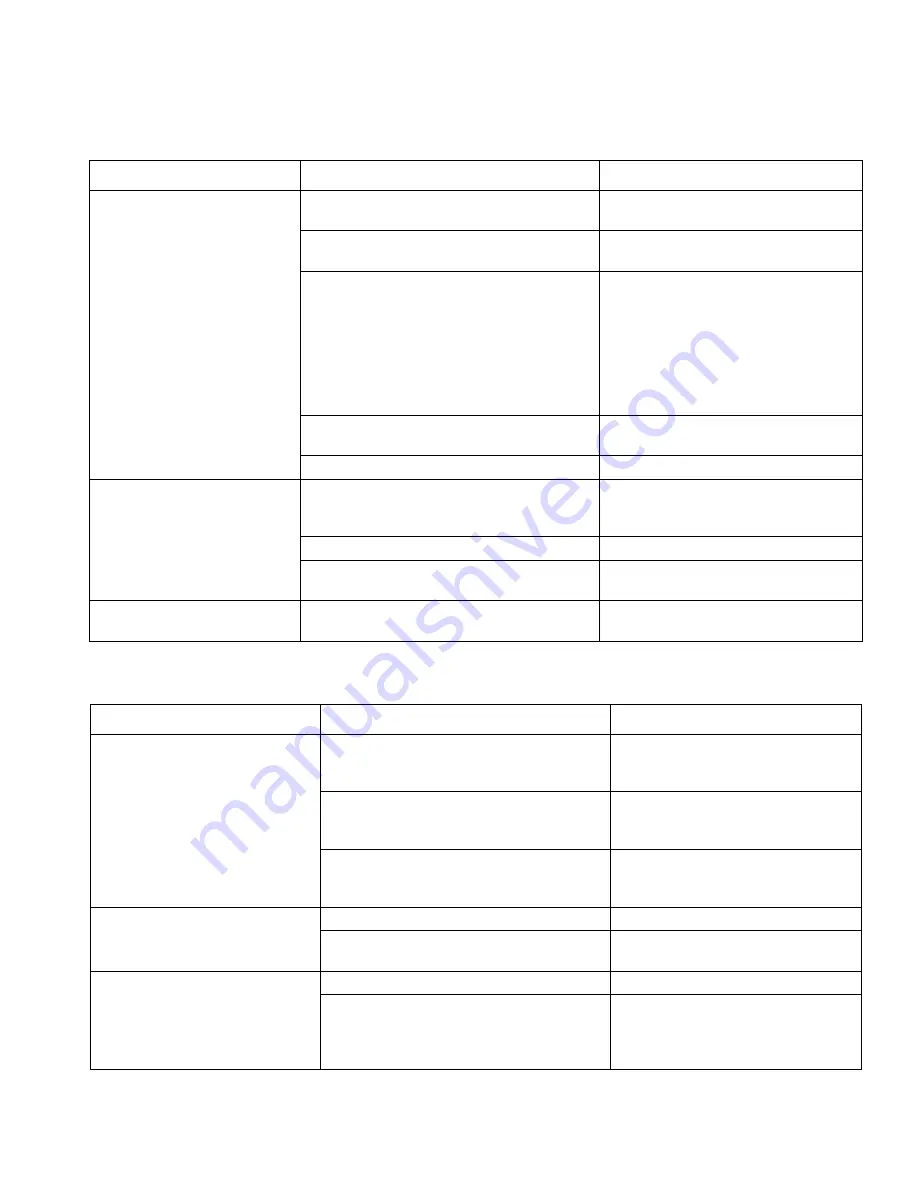

Low or Fluctuating Output (continued)

Electrical Short

PROBLEM

CAUSE

SOLUTION

Motor runs and pump strokes

No material supply.

Refill hopper and re-prime pump.

Clean hopper strainer.

Loose fittings.

Tighten; use thread sealant or sealing

tape on threads if necessary.

Intake valve ball and piston ball are not seat-

ing properly.

Remove intake and piston valves and

clean. Check balls and seats for nicks or

obstructions; replace if necessary, page

18. Also check piston valve seat for

hardened material or nicks and replace

if necessary. Clean hopper before using

to remove particles that could clog

pump.

Leaking around throat packing nut which may

indicate worn or damaged packings.

Replace packing, page 18.

Pump rod damage.

Repair pump.

Motor runs but pump does not

stroke

Displacement pump pin (damaged or miss-

ing).

Replace pump pin if missing. Be sure

retainer spring (76) is fully in groove all

around connecting rod.

Connecting rod assembly is damaged.

Replace connecting rod assembly.

Gears or drive housing.

Inspect drive housing assembly and

gears for damage. Replace if needed.

Motor intermittently stops while

applying material

See RF Problems, page 18.

PROBLEM

CAUSE

SOLUTION

Building circuit breaker opens as

soon as power switch is turned on.

CAUTION

Any short in any part of the motor

power circuit will cause the control

circuit to inhibit drywall feed pump

operation. Correctly diagnose and

repair all shorts before checking

and replacing control board.

Electrical wiring insulation damaged, termi-

nals fit loose or are damaged. Also wires

between motor control and motor.

Repair or replace damaged wiring or

terminals. Securely reconnect all

wires.

Motor armature is shorted.

Replace motor. Inspect windings for

burns. Perform motor control board

diagnosis.

Motor control board.

Replace with a new control board if

necessary. Perform motor control

board diagnosis.

Building circuit breaker opens as

soon as unit is plugged into outlet

and unit is NOT turned on.

Basic Electrical Problems, see page 15.

Perform necessary procedures.

For damaged or pinched wires in pressure

control.

Replace damaged parts.

Drywall feed pump quits after unit

operates for 5 to 10 minutes.

Basic Electrical Problems.

Perform necessary procedures.

Check electrical supply with volt meter.

Meter must read:

210-255 Vac for 220-240 Vac models;

85-130 Vac for 100-120 Vac models.

If voltage is too high, do not operate

drywall feed pump until corrected.

Summary of Contents for 257100

Page 30: ...Notes 30 3A0245A Notes...