308442 23

Troubleshooting

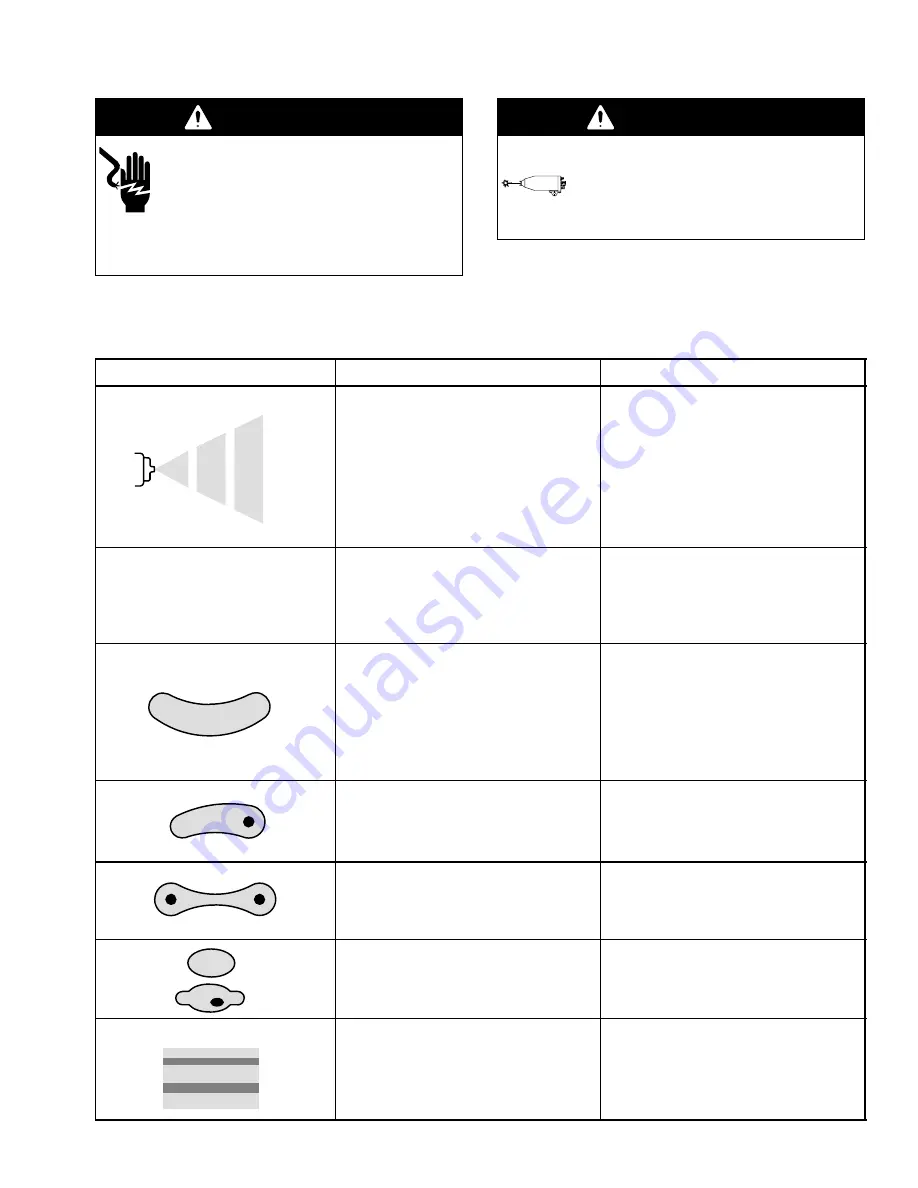

WARNING

ELECTRIC SHOCK HAZARD

Installing and servicing this equipment

requires access to parts which may

cause an electric shock or other serious

injury if the work is not performed prop-

erly. Do not install or service this equipment unless

you are trained and qualified.

WARNING

PRESSURIZED EQUIPMENT

To reduce the risk of a serious injury,

follow the Pressure Relief Procedure

on page 16 before doing any mainte-

nance or service on the gun or system.

NOTE: Check all possible remedies in the Troubleshooting Charts before disassembling the gun.

Spray Pattern Troubleshooting

NOTE: Some spray pattern problems are caused by the improper balance between air and fluid.

PROBLEM

CAUSE

SOLUTION

Fluttering or spitting spray

The fluid supply is insufficient.

The fluid nozzle is loose, or the fluid noz-

zle taper seat is damaged.

There is dirt between the fluid nozzle,

taper seat, and gun body.

The coupler at the fluid inlet is loose or

cracked.

Adjust the fluid regulator, or fill the fluid

tank.

Tighten or replace the fluid nozzle; see

page 29.

Clean the parts; see page 21.

Tighten or repair the coupler.

Gun is spitting when triggered or

detriggered.

The air cap is damaged or dirty.

The actuator arm is out of position (it is too

close to the fluid needle).

The fluid seat is worn.

Clean or replace the air cap; see page 21.

Reposition the actuator arm; see page 32.

Replace the fluid nozzle and/or electrode

needle; see page 29 and 30.

There is fluid buildup on the air cap; par-

tially clogged horn holes; or full air pres-

sure from the clean horn hole forces the

fan pattern toward the clogged end.

The electrode is bent.

The fluid nozzle or air cap holes are dam-

aged.

Clean the air cap with a soft implement or

submerge it in water and wipe it clean;

see page 21.

Straighten the electrode.

Replace the damaged part; see page 29.

There is fluid buildup on the perimeter of

the fluid nozzle orifice, or a partially

clogged fluid nozzle orifice.

The electrode is bent.

Remove the obstruction; never use wire

or hard instruments; see page 21.

Straighten the electrode.

The fan air pressure is too high.

The fluid is too thin.

There is not enough fluid pressure.

Reduce the fan air pressure.

Increase the fluid viscosity.

Increase the fluid pressure.

The fan air pressure is too low.

The fluid is too thick.

There is too much fluid.

Increase the fan air pressure.

Reduce the fluid viscosity.

Reduce the fluid flow.

Streaks

The last coat of fluid is applied too wet.

There is too much air pressure.

The air pressure is insufficient.

The spray pattern is non-uniform.

Apply a drier finish using multiple strokes.

Decrease the air pressure.

Increase the air pressure.

Clean or replace the air cap; see page 21.